China Hydraulic Valve Operation: OEM Factory Insights on Working Principles and Products

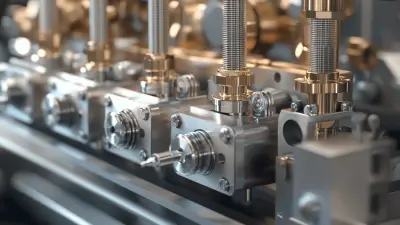

Ningbo Longerfa Hydraulic Co., Ltd. specializes in advanced hydraulic valve solutions tailored to meet the unique demands of various industries. Our products ensure reliable performance and exceptional durability, effectively controlling the flow and pressure of hydraulic fluids through precise mechanisms. Crafted with cutting-edge technology, our valves feature robust construction and innovative engineering, making them suitable for applications in construction machinery and industrial equipment. Designed for maximum efficiency, our hydraulic valves reduce energy consumption while optimizing output. At Ningbo Longerfa, we prioritize quality and customer satisfaction, backed by our experienced team dedicated to high industry standards. Enhance your operations with our exceptional hydraulic valve solutions, and experience the benefits of our expertise and innovation.10 Essential Tips For China Hydraulic Valve Working Principle Global Reach Application

Hydraulic valves play a crucial role in various industrial applications, ensuring optimal performance and efficiency. At Ningbo Longerfa Hydraulic Co., Ltd., a recognized high-tech enterprise specializing in hydraulic valve manufacturing, we understand the importance of quality and innovation in Hydraulic Systems. Here are ten essential tips for understanding the working principles of hydraulic valves and their global applications. Firstly, grasping the fundamentals of hydraulic valve mechanics is vital. Hydraulic valves control the flow and direction of fluid within a system, which directly impacts machinery performance. Understanding how different valve designs, such as the hydraulic valve set and hydraulic thread plug valve, operate can help buyers select the right components for their unique needs. Prioritize sourcing from reputable manufacturers, like Longerfa, known for their commitment to quality standards and advanced R&D capabilities. Secondly, consider the diverse applications of hydraulic valves across industries—from construction and agriculture to manufacturing and aerospace. As global demand surges, it's essential to recognize how compatibility with various hydraulic systems can enhance operational efficiency. Look for manufacturers who not only provide a wide range of hydraulic components but also offer expertise in customization and integration to meet specific project requirements. By collaborating with a reliable partner, you can ensure that your hydraulic solutions are robust and suitable for global applications.

10 Essential Tips For China Hydraulic Valve Working Principle Global Reach Application

| Tip No. | Tip Description | Application Area | Expected Benefits |

|---|---|---|---|

| 1 | Understand the Basic Principle of Operation | Manufacturing, Maintenance | Enhanced troubleshooting skills |

| 2 | Choose the Right Type of Valve | Construction, Automotive | Increased efficiency and safety |

| 3 | Regular Maintenance and Inspection | Industrial Machinery | Prolonged lifespan of equipment |

| 4 | Understand Flow Rates and Pressure Ratings | Fluid Control Systems | Optimized operational performance |

| 5 | Educate Staff on Safety Procedures | Workshops, Training Centers | Reduction in workplace accidents |

| 6 | Optimize System Design for Efficiency | Engineering, R&D | Maximized output with less energy |

| 7 | Use Quality Components and Materials | Manufacturing | Improved reliability and durability |

| 8 | Implement Advanced Control Systems | Automation, Robotics | Enhanced precision and control |

| 9 | Take Advantage of Training and Workshops | Industry Events | Stay updated on new technologies |

| 10 | Ensure Compliance with International Standards | Global Trade | Market access and credibility |

Must-See List China Hydraulic Valve Working Principle Factory-Direct Excellence Now Trending

S

Sarah Davis

This product has truly transformed my experience. The follow-up from their support team was both timely and informative.

29 June 2025

S

Sophia Garcia

Wonderful product! Their after-sales service was clear and extremely professional.

08 June 2025

V

Victoria Martin

I couldn’t be happier with this product! The follow-up service was top-notch and incredibly professional.

21 June 2025

C

Cameron Robinson

Exceptional value for the quality! Their support team was very helpful in assisting me.

03 July 2025

C

Caleb Adams

High-quality product! Their customer service offered invaluable assistance during my purchase.

25 June 2025

S

Sophie Martin

Incredible product! The post-purchase assistance from their support team was highly professional.

19 May 2025