Check Valve Working Principle: Essential OEM Insights for Factories and Products

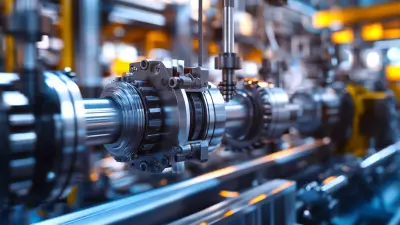

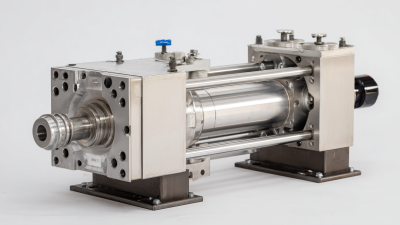

Check valves are critical components in hydraulic systems, ensuring unidirectional fluid flow and preventing backflow. At Ningbo Longerfa Hydraulic Co., Ltd., our expertise lies in manufacturing top-quality check valves crafted to optimize the efficiency and safety of various applications. Our products leverage advanced engineering and robust materials, ensuring they can endure high pressure and harsh conditions. The innovative spring-loaded mechanism reacts promptly to pressure changes, guaranteeing reliable performance with minimal maintenance. Precise sealing technology provides a tight closure, significantly reducing the risk of leaks and enhancing overall system reliability. Ideal for industrial machinery, automotive uses, and diverse hydraulic setups, our check valves are synonymous with exceptional reliability and durability. Committed to quality and customer satisfaction, Ningbo Longerfa Hydraulic Co., Ltd. delivers products that conform to the highest industry standards, ensuring seamless and secure operation in your hydraulic systems.

In-Depth Analysis of Methods Check Valve Working Principle Factory Market Leader Global Reach

In-Depth Analysis of Methods Check Valve Working Principle Factory Market Leader Global Reach

| Method | Working Principle | Material | Size Range (inches) | Market Share (%) | Global Reach (Countries) |

|---|---|---|---|---|---|

| Swing Check Valve | Uses a swinging disc to allow flow in one direction. | Cast iron, stainless steel | 2 - 48 | 30 | USA, Canada, Europe, Asia |

| Lift Check Valve | Employs a lifting mechanism to prevent backflow. | Brass, bronze, plastic | 1 - 20 | 25 | North America, South America, Australia |

| Ball Check Valve | Uses a ball to block flow; moves with fluid pressure. | PVC, stainless steel | 0.5 - 12 | 20 | Asia, Europe, Africa |

| Solenoid Check Valve | Electromagnetically operated valve to control flow. | Aluminum, stainless steel | 1 - 6 | 15 | Global |