In the realm of industrial applications, the selection of the right components is crucial for optimal performance and efficiency. Stacked Counterbalance Valves are increasingly recognized for their ability to manage loads effectively and enhance system reliability. These specialized valves not only provide necessary control over hydraulic systems but also ensure safety during operation by preventing unintended movements of machinery.

As industries strive for higher productivity and safety measures, understanding the key criteria for choosing Stacked Counterbalance Valves becomes paramount. This blog aims to provide a comprehensive checklist that outlines essential factors, including pressure ratings, system compatibility, and flow characteristics, to assist engineers and decision-makers in making informed choices. By focusing on these critical aspects, we will explore how to maximize the benefits of Stacked Counterbalance Valves in various industrial settings.

As industries strive for higher productivity and safety measures, understanding the key criteria for choosing Stacked Counterbalance Valves becomes paramount. This blog aims to provide a comprehensive checklist that outlines essential factors, including pressure ratings, system compatibility, and flow characteristics, to assist engineers and decision-makers in making informed choices. By focusing on these critical aspects, we will explore how to maximize the benefits of Stacked Counterbalance Valves in various industrial settings.

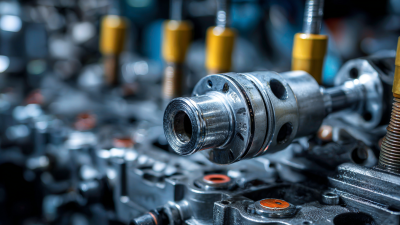

Stacked counterbalance valves play a crucial role in hydraulic systems, particularly in industrial applications where

load control and safety are paramount. These valves are designed to maintain static loads and prevent uncontrolled movements, making them an essential component for

machinery operating in dynamic environments. A key feature of stacked counterbalance valves is their ability to provide precise load management, allowing operators to lift and lower loads with confidence. This precision

ensures that equipment operates smoothly and safely, reducing the risk of accidents and enhancing productivity.

Stacked counterbalance valves play a crucial role in hydraulic systems, particularly in industrial applications where

load control and safety are paramount. These valves are designed to maintain static loads and prevent uncontrolled movements, making them an essential component for

machinery operating in dynamic environments. A key feature of stacked counterbalance valves is their ability to provide precise load management, allowing operators to lift and lower loads with confidence. This precision

ensures that equipment operates smoothly and safely, reducing the risk of accidents and enhancing productivity.

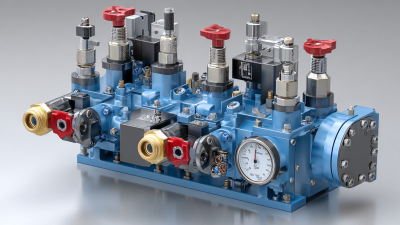

Another significant benefit of stacked counterbalance valves is their space-saving design. By integrating multiple functions into a compact stack, these valves minimize the complexity of hydraulic circuits while maximizing efficiency. This streamlined approach not only simplifies installation but also enhances maintenance processes. Additionally, operators can easily adjust the system parameters to suit specific application requirements, leading to improved operational flexibility. As industries increasingly prioritize efficiency and safety, understanding the key features and benefits of stacked counterbalance valves becomes essential for making informed decisions in hydraulic system design.

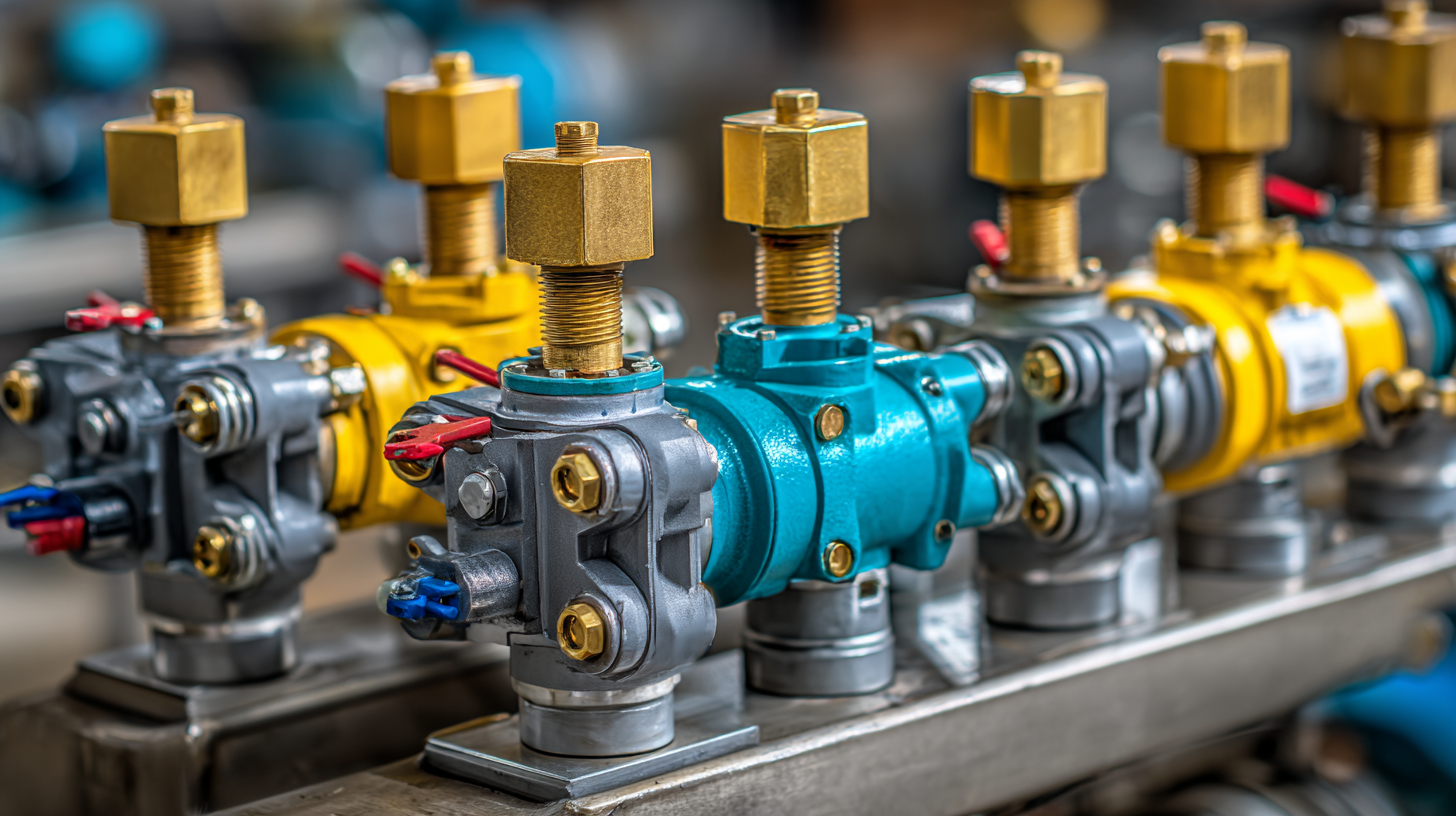

When selecting stacked counterbalance valves for industrial applications, several critical factors come into play. First and foremost, understanding the specific requirements of your system is essential. This includes the expected load conditions, the type of hydraulic fluid used, and the operational environment. Different applications might demand varying levels of responsiveness and stability from the control system; thus, matching the valve’s specifications with your operational parameters is key.

Another vital consideration is the valve’s pressure-handling capability. Stacked counterbalance valves should have a pressure rating that suits your system's maximum operating pressure to ensure safe and reliable performance. Additionally, look into the valve's flow characteristics, ensuring it can manage the flow rates necessary for your machinery without leading to inefficiencies. Lastly, evaluating the ease of installation and maintenance of these valves can save significant time and costs in the long run, making it an essential criterion for decision-making in your selection process.

| Factor | Description | Importance Level | Recommended Specifications |

|---|---|---|---|

| Pressure Rating | Maximum operating pressure the valve can handle. | High | At least 3000 psi |

| Flow Rate | Volume of fluid passing through the valve per unit time. | Medium | 5-40 GPM |

| Temperature Range | Operating temperature limits for the valve. | Medium | -20°F to 180°F |

| Response Time | Time taken for the valve to react to a signal. | High | Less than 50 ms |

| Mounting Style | How the valve integrates with the system. | Medium | Stacked or modular configuration |

| Material Compatibility | The materials that may contact the hydraulic fluid. | High | Steel or aluminum with anti-corrosion treatment |

| Regulatory Compliance | Compliance with industry standards. | High | ISO 9001 certified |

When it comes to selecting counterbalance valves for industrial applications, understanding the differences between stacked and traditional counterbalance valves is crucial.

Stacked counterbalance valves are designed to provide multiple functions in a single compact unit, offering benefits like reduced installation time and minimized plumbing requirements. This design allows for a more organized layout and can enhance the overall efficiency of hydraulic systems. Furthermore, stacked valves often incorporate advanced features such as integrated pressure relief, which can lead to improved performance and reliability in demanding environments.

On the other hand, traditional counterbalance valves are typically standalone components and may require more space and more time for installation. While they can be very effective, their single-function nature means that they might not offer the same level of integration and efficiency as their stacked counterparts. This distinction becomes particularly important in applications where space is at a premium or where operational efficiency needs to be maximized. Ultimately, the choice between stacked and traditional counterbalance valves will depend on the specific requirements of the application, including factors like available space, system complexity, and desired performance characteristics.

Stacked counterbalance valves play a pivotal role in a variety of industrial applications, ensuring that hydraulic systems operate safely and efficiently. These valves are particularly essential in scenarios where load control is critical, such as in mobile equipment, manufacturing machinery, and material handling systems. They help prevent uncontrolled descent of loads, allowing operators to maintain control over heavy equipment during lifting operations.

When selecting stacked counterbalance valves, one tip is to evaluate the specific requirements of your application. Consider factors such as load weight, speed of movement, and frequency of use. This will help you determine the appropriate specifications and configurations needed to achieve optimal performance. Additionally, ensure compatibility with existing hydraulic systems to avoid integration issues later on.

Another important consideration is the valve's response time and sensitivity. Quick response is crucial in applications that require precise load control, such as cranes and aerial lifts. Regularly review system performance and make adjustments as necessary, as this proactive maintenance can significantly enhance operational efficiency and safety. Always consult with a knowledgeable supplier or manufacturer to ensure the selected valve meets the demands of your specific application.

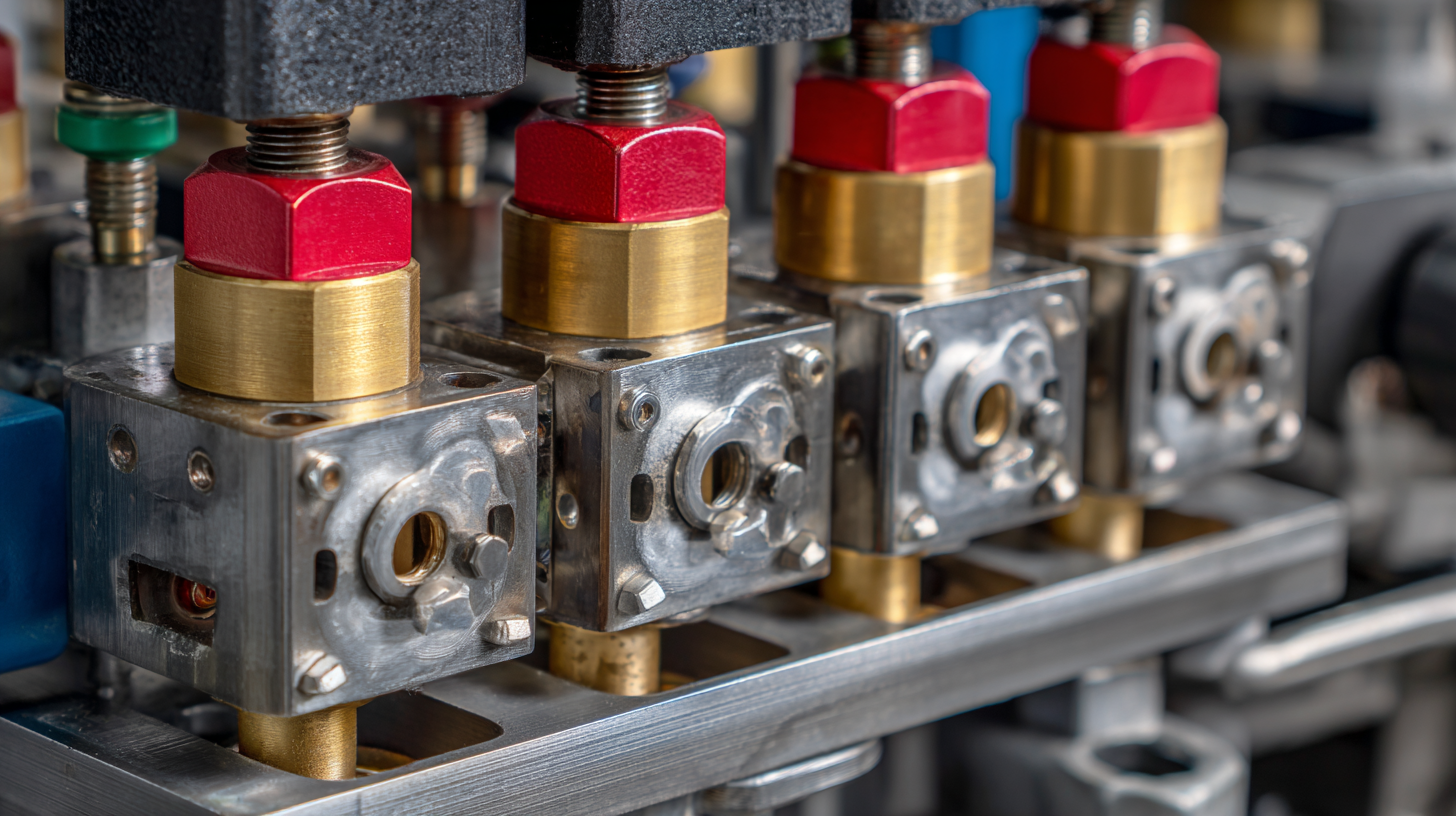

As industries evolve, the demand for more efficient and reliable hydraulic systems has led to significant innovations in

stacked counterbalance valve technology.

Manufacturers are exploring advanced materials and designs that enhance the performance and longevity of these valves. A notable trend is the integration of

smart technologies, such as IoT capabilities, allowing for real-time monitoring and control of hydraulic systems. This not only improves operational efficiency but also facilitates

predictive maintenance, reducing downtime and operational costs.

Another emerging trend is the focus on

energy efficiency. With increasing pressure to reduce energy consumption, new valve designs are prioritizing minimal hydraulic losses. Enhanced flow characteristics and refined internal geometries are being developed to promote smoother operation and reduce the overall environmental footprint of industrial applications. Furthermore, the adoption of modular systems enables easier configuration and scalability, accommodating diverse application needs and future expansions.

These innovations promise to revolutionize how stacked counterbalance valves are utilized in various industries, paving the way for more sustainable and effective hydraulic solutions.