In the evolving landscape of industrial automation, the demand for Unidirectional Throttle Valves has surged, driven by a variety of factors including the growth of the manufacturing sector and advancements in fluid control technology. According to a recent market analysis by ResearchAndMarkets, the global market for throttle valves is anticipated to reach $5.4 billion by 2026, expanding at a compound annual growth rate (CAGR) of 4.5%. This growth is indicative of the increasing reliance on precision engineering in industries such as automotive, aerospace, and pharmaceuticals, where the performance of Unidirectional Throttle Valves directly impacts operational efficiency and safety. As companies seek to enhance their sourcing strategies, understanding industry trends and leveraging data-driven insights will be crucial for procurement professionals aiming to navigate this competitive market effectively. This blog aims to explore the top strategies for sourcing Unidirectional Throttle Valves, ensuring that businesses are well-equipped to meet their evolving needs.

When selecting unidirectional throttle valves for various applications, it's crucial to consider multiple factors that impact performance and efficiency. According to a recent report by MarketsandMarkets, the global throttle valve market is projected to grow from USD 4.5 billion in 2021 to USD 6.2 billion by 2026, signifying a robust demand driven by industrial automation and control systems. This growth reflects the increasing need for precise flow control in sectors such as automotive, aerospace, and manufacturing.

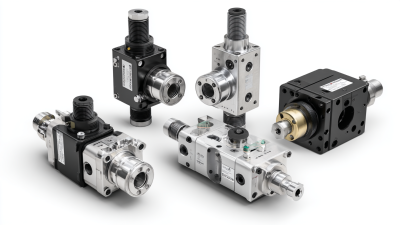

Key considerations include the valve's material, size, and pressure rating. For instance, high-performance applications may require valves made from stainless steel or specialized alloys, whereas standard applications could utilize more cost-effective materials like PVC. A study published by TechSci Research highlights that applications requiring high temperature and pressure resistance demand careful evaluation of valve specifications. Additionally, consumers should assess compatibility with existing systems to avoid costly retrofitting. With thoughtful selection informed by industry trends and data, organizations can optimize their operational efficiency and maintain competitive advantage.

The sourcing of unidirectional throttle valves is increasingly shaped by prevailing industry trends, particularly within the Engineering, Procurement, and Construction Management (EPCM) sector. By 2032, the EPCM market is projected to soar from $499 million in 2024 to a staggering $953.2 billion, indicating an annual growth rate of 8.42%. This sharp rise highlights a growing demand for precision-engineered components, such as unidirectional throttle valves, that meet the evolving needs of various industries, including healthcare and robotics.

In the healthcare sector, a significant policy push is bolstering the construction of grassroots medical facilities, with a corresponding increase in the demand for domestic equipment procurement. This surge aligns with the recovering trends in clinical equipment purchases and the rising need for medical consumables. Additionally, the robotics industry is witnessing substantial investments, driven by government initiatives and substantial funding to foster technological innovation. By understanding these trends, manufacturers and suppliers can better position themselves in the market, ensuring that their sourcing strategies are aligned with the future demands of both the healthcare and robotics sectors.

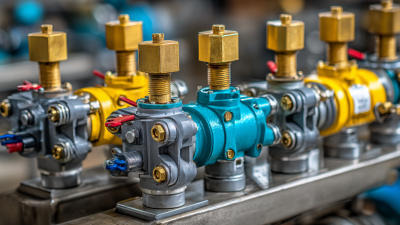

When sourcing unidirectional throttle valves, evaluating potential suppliers is crucial for ensuring product quality and reliability. Essential data metrics play a key role in this evaluation process. First and foremost, examining the supplier's production volume and capacity can provide insights into their ability to meet demand fluctuations. A manufacturer that demonstrates a consistent production history and has the capacity to scale operations can be a reliable partner.

Additionally, assessing quality control metrics, such as defect rates and compliance with industry standards, is vital. Suppliers that adhere to certifications like ISO 9001 not only ensure that their products meet stringent quality benchmarks but also provide transparency regarding their manufacturing processes. Furthermore, analyzing customer feedback and satisfaction ratings can reveal important information about the supplier’s performance in real-world applications. By focusing on these essential data metrics, companies can make informed decisions that lead to successful partnerships in the sourcing of unidirectional throttle valves.

Negotiating contracts with valve manufacturers, particularly for unidirectional throttle valves, requires a strategic approach grounded in industry insights. One of the best practices is to conduct thorough market research before entering negotiations. Understanding the current market trends, competitive pricing, and the unique features of various manufacturers’ offerings can provide leverage during discussions. It's essential to identify your specific needs and ensure that potential suppliers align with your technical specifications and quality standards. This preparation not only establishes a solid foundation for negotiations but also builds rapport with manufacturers.

Another key aspect is fostering open communication throughout the negotiation process. Clearly articulating your requirements and expectations can lead to more productive discussions. Be prepared to discuss pricing, delivery timelines, and support services in detail. Additionally, exploring volume discounts or long-term contracts can be advantageous. Effective negotiation is about finding a mutually beneficial agreement that enhances collaboration with manufacturers while ensuring you receive the best value for your investment. Establishing a strong relationship during the contract phase can lead to improved service and support in the future, creating a win-win situation for both parties involved.

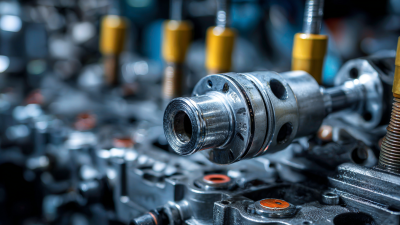

The landscape of throttle valve sourcing is undergoing a significant transformation, driven by emerging technologies that are reshaping the industry.

According to a report by MarketsandMarkets, the global throttle valve market is projected to reach USD 5.2 billion by 2025, growing at a CAGR of 5.3%. This growth is largely fueled by advancements such as IoT integration, which enhances real-time monitoring of valve performance, leading to improved efficiency and reduced downtime in manufacturing processes.

Moreover, the rise of additive manufacturing technologies, or 3D printing, is revolutionizing the sourcing of unidirectional throttle valves. A study by Deloitte highlights that 71% of companies in the manufacturing sector are actively exploring 3D printing to reduce material waste and shorten lead times. By leveraging these innovative production methods, companies can create custom throttle valves that meet specific operational requirements while minimizing traditional supply chain complexities. As more organizations adopt these technologies, sourcing strategies will evolve, emphasizing agility and adaptability in response to shifting market demands.