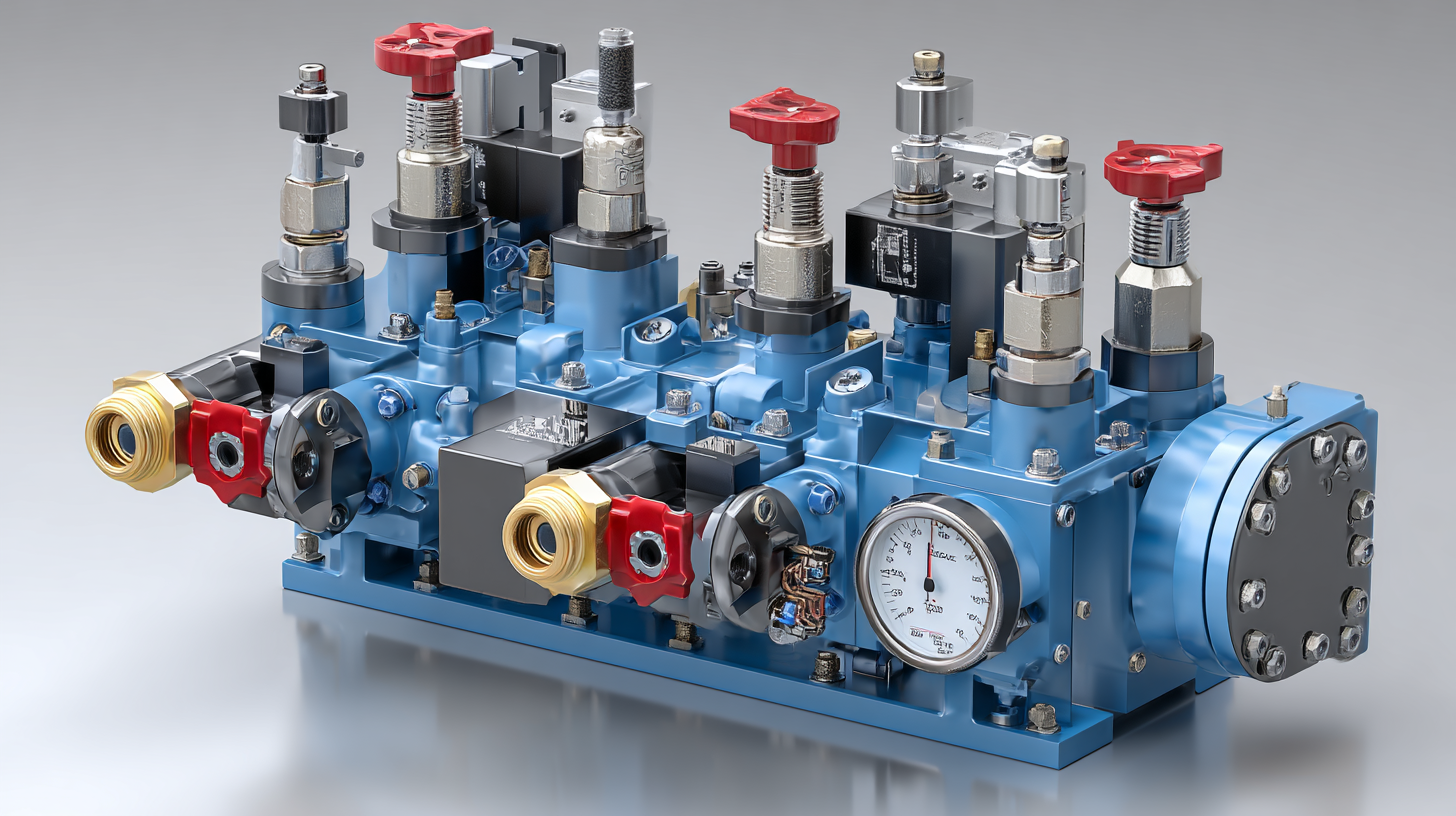

In the ever-evolving landscape of manufacturing, the adoption of advanced technologies is paramount, particularly with innovations like the Hydraulic Lift Valve Manifold. This component plays a crucial role across key industries, including automotive, aerospace, construction, and material handling, as reported by the MarketsandMarkets Industrial Automation report, which predicts a growth of the hydraulic components market to reach USD 24.6 billion by 2025. The versatility and efficiency of hydraulic systems have led to a surge in demand, driven by their ability to improve operational productivity and reduce downtime. With a focus on understanding the distinct characteristics and applications of different product types, this blog will explore the significant reasons behind the shift toward Hydraulic Lift Valve Manifolds and how their integration dramatically enhances manufacturing processes across various sectors.

The evolution of hydraulic lift valve manifolds in modern manufacturing is a testament to the continual advancement in engineering and technology. Over the past few decades, these systems have transformed from rudimentary designs to sophisticated components that enhance efficiency and performance across various industries. Recent data suggests that the global market for hydraulic systems is expected to reach $50 billion by 2025, driven by increased automation and the demand for precision in manufacturing processes.

Key innovations in hydraulic lift valve manifolds include the integration of smart technologies, enabling real-time monitoring and adaptive control. This evolution mirrors trends seen in the automotive sector, where engine designs like the new iterations have shifted towards lightweight materials and optimal airflow, improving fuel efficiency and performance. Industry reports indicate that manufacturers adopting advanced hydraulic manifolds experience efficiency boosts of up to 30%, positioning them competitively in a rapidly evolving marketplace. The continuous refinement of hydraulic lift systems signifies a broader commitment to innovation, highlighting the necessity for industries to embrace these changes for sustained growth and operational excellence.

In today's competitive landscape, several key industries are transforming their operations with advanced hydraulic solutions, particularly emphasizing the adoption of hydraulic lift valve manifolds. The manufacturing sector, which accounts for approximately 16% of the global GDP according to the World Bank, reveals a growing trend towards automation and efficiency. Hydraulic systems, known for their reliability and power, play a crucial role in enabling manufacturers to streamline processes, reduce downtime, and enhance productivity.

The construction and heavy machinery sectors are also reaping significant advantages from hydraulic innovations. The global construction equipment market is projected to reach $250 billion by 2025, according to a report by Grand View Research. Hydraulic lift valve manifolds facilitate greater control of machinery, allowing for precise movements and improved operational output. Furthermore, in the automotive industry, hydraulic systems contribute to better design flexibility and performance, positioning companies to adapt swiftly to market demands as noted by recent analyses from the Automotive Data Network.

Additionally, the aerospace industry has recognized the importance of hydraulic solutions, with values projected to exceed $250 billion by 2026 as detailed in a report by MarketsandMarkets. The integration of hydraulic lift valve manifolds in this industry enhances safety by offering fail-safe mechanisms and ensures that complex systems function smoothly under extreme conditions. Consequently, the shift towards hydraulic systems not only drives operational excellence but also supports innovation across various sectors.

The manufacturing industry is witnessing a significant transformation, with hydraulic lift valve manifolds leading the charge in enhancing operational efficiency. One of the primary reasons manufacturers are embracing these systems is their ability to streamline processes. The integration of hydraulic systems minimizes manual labor, allowing for automated movements that can drastically reduce cycle times and enhance productivity.

The manufacturing industry is witnessing a significant transformation, with hydraulic lift valve manifolds leading the charge in enhancing operational efficiency. One of the primary reasons manufacturers are embracing these systems is their ability to streamline processes. The integration of hydraulic systems minimizes manual labor, allowing for automated movements that can drastically reduce cycle times and enhance productivity.

Another compelling reason is the versatility that hydraulic lift valve manifolds bring to various applications. Whether in automotive assembly lines, aerospace manufacturing, or heavy machinery production, these systems can be tailored to meet the diverse needs of different industries. Moreover, reducing energy consumption is a crucial factor, as hydraulic systems tend to offer more efficient energy usage compared to traditional mechanical systems, leading to significant cost savings over time.

Additionally, the reduced maintenance requirements associated with hydraulic lift valve manifolds play a vital role in their adoption. These systems are designed to be robust and reliable, significantly lowering the chances of downtime due to mechanical failure. As manufacturers continuously seek ways to enhance productivity, safety, and profitability, it’s clear why hydraulic lift valve manifolds are becoming a cornerstone of modern manufacturing strategies.

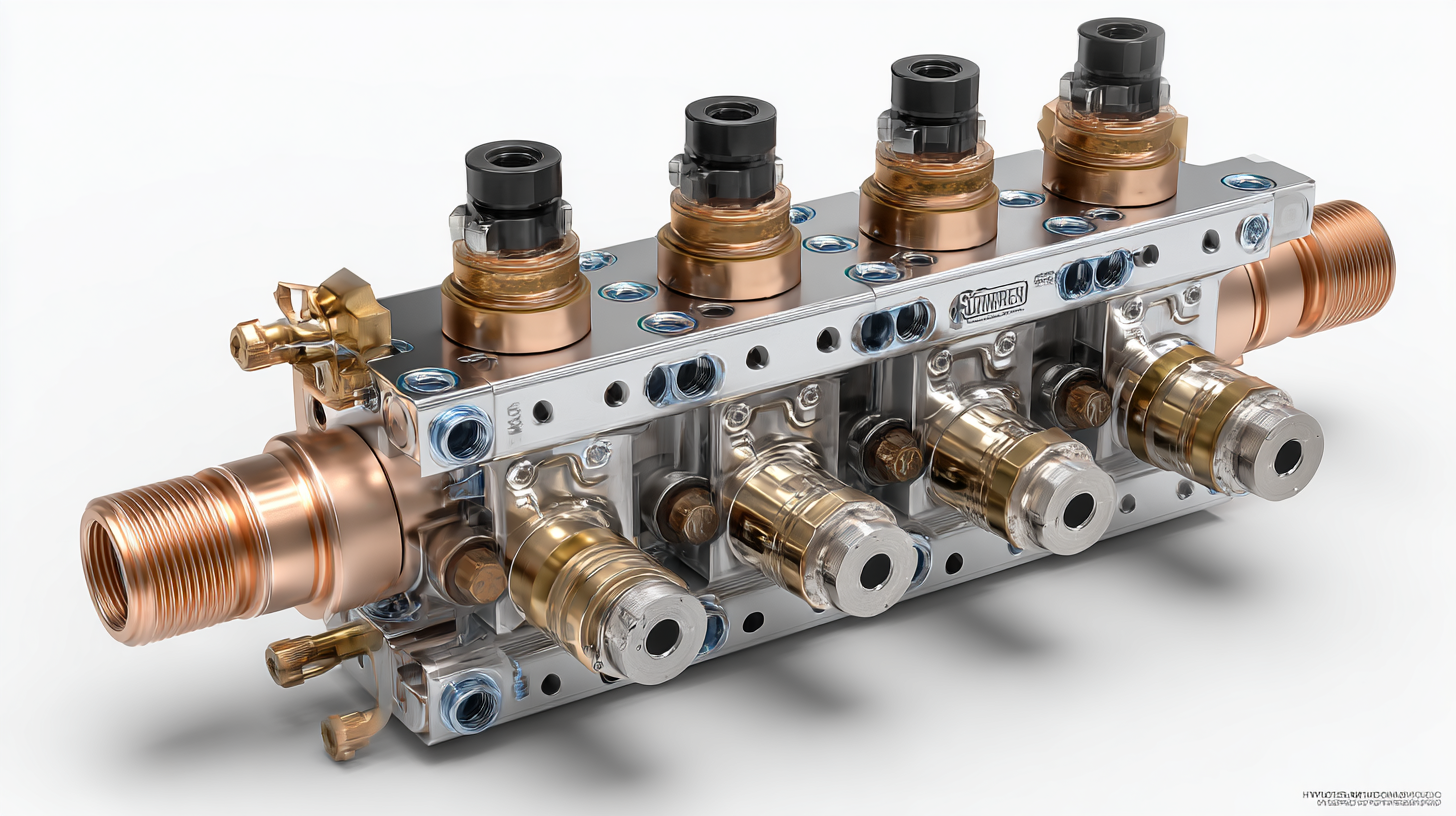

The integration of advanced hydraulic technologies is redefining industrial efficiency across various sectors. Recent analyses indicate that the global hydraulic seals market is projected to experience substantial growth, driven by a rising demand for hydraulic piston seals and rod seals, with notable implications for manufacturing precision. Advanced hydraulic valve manifolds are pivotal in optimizing fluid power systems, as their utilization in key industries such as construction, automotive, and agriculture enables significant improvements in operational performance.

Moreover, the mobile hydraulic equipment market is expected to flourish, with a compound annual growth rate (CAGR) of 6.1%. This growth is fueled by innovations that streamline hydraulic system designs, allowing for enhanced functionality and reduced energy consumption. The convergence of AI and machine learning with fluid power systems further amplifies these benefits, facilitating predictive maintenance and operational efficiencies that were previously unattainable. As industries embrace these technological advancements, the significance of hydraulic systems in achieving sustainability and operational excellence becomes ever more apparent.

Chinese manufacturing is rapidly establishing itself as a benchmark for quality, particularly in the hydraulic components sector. As industries across the globe embrace advanced technology, the demand for high-quality hydraulic products has surged. This shift is evident in the rising profiles of Chinese manufacturers, who are not only meeting but often exceeding international standards in hydraulic valve production. Their commitment to quality and innovation plays a crucial role in meeting the needs of diverse sectors, including automotive, construction, and energy.

The global hydraulic valve market is projected to experience significant growth, driven by advancements in manufacturing techniques and the increasing application of hydraulic systems. China's role in this landscape cannot be overstated. As local manufacturers optimize processes and integrate cutting-edge technology, they're ensuring that their hydraulic components meet stringent performance criteria. This dedication not only enhances the reliability of hydraulic systems worldwide but also serves as a competitive advantage in an increasingly globalized marketplace, showcasing China's capacity to set the standard in hydraulic component quality.