In today's industrial landscape, the selection of the right components is crucial for operational efficiency and productivity. Among these components, Logic Element Valves stand out as essential tools that can significantly influence system performance and reliability. Understanding the unique features and applications of various types of Logic Element Valves is critical for manufacturers and engineers aiming to optimize their processes.

These valves not only control the flow of fluids but also enhance automation and responsiveness within complex systems. This blog will delve into the different types of Logic Element Valves, highlighting their characteristics, benefits, and optimal use cases. By gaining insights into these components, businesses can make informed decisions that align with their specific industrial needs.

These valves not only control the flow of fluids but also enhance automation and responsiveness within complex systems. This blog will delve into the different types of Logic Element Valves, highlighting their characteristics, benefits, and optimal use cases. By gaining insights into these components, businesses can make informed decisions that align with their specific industrial needs.

When selecting logic element valves for industrial applications, several key considerations can significantly impact both efficiency and effectiveness. First and foremost, understanding the specific requirements of your operation, such as flow rate and pressure conditions, is crucial. According to a recent market research report by Industry Insights Inc., nearly 30% of valve failures are attributed to improper specifications during the selection process. This statistic underscores the importance of thorough analysis to match valve capabilities with system demands.

Another vital factor to consider is the valve material and construction. Different environments can expose valves to various corrosive substances, making it essential to choose materials that ensure durability and reliability. A study from the Valve Manufacturers Association (VMA) indicates that using the right material can extend valve life by nearly 50%.

Tips: Always consult with valve manufacturers during the selection process to optimize performance for your specific operational environment. Additionally, conduct regular maintenance checks to preemptively identify any wear or malfunction in the logic element valves to ensure sustained operational efficiency.

When it comes to industrial processes,

logic element valves

play a crucial role in controlling fluid flow and ensuring system efficiency. Understanding the different types of logic element valves is essential for selecting the optimal solution for your specific needs.

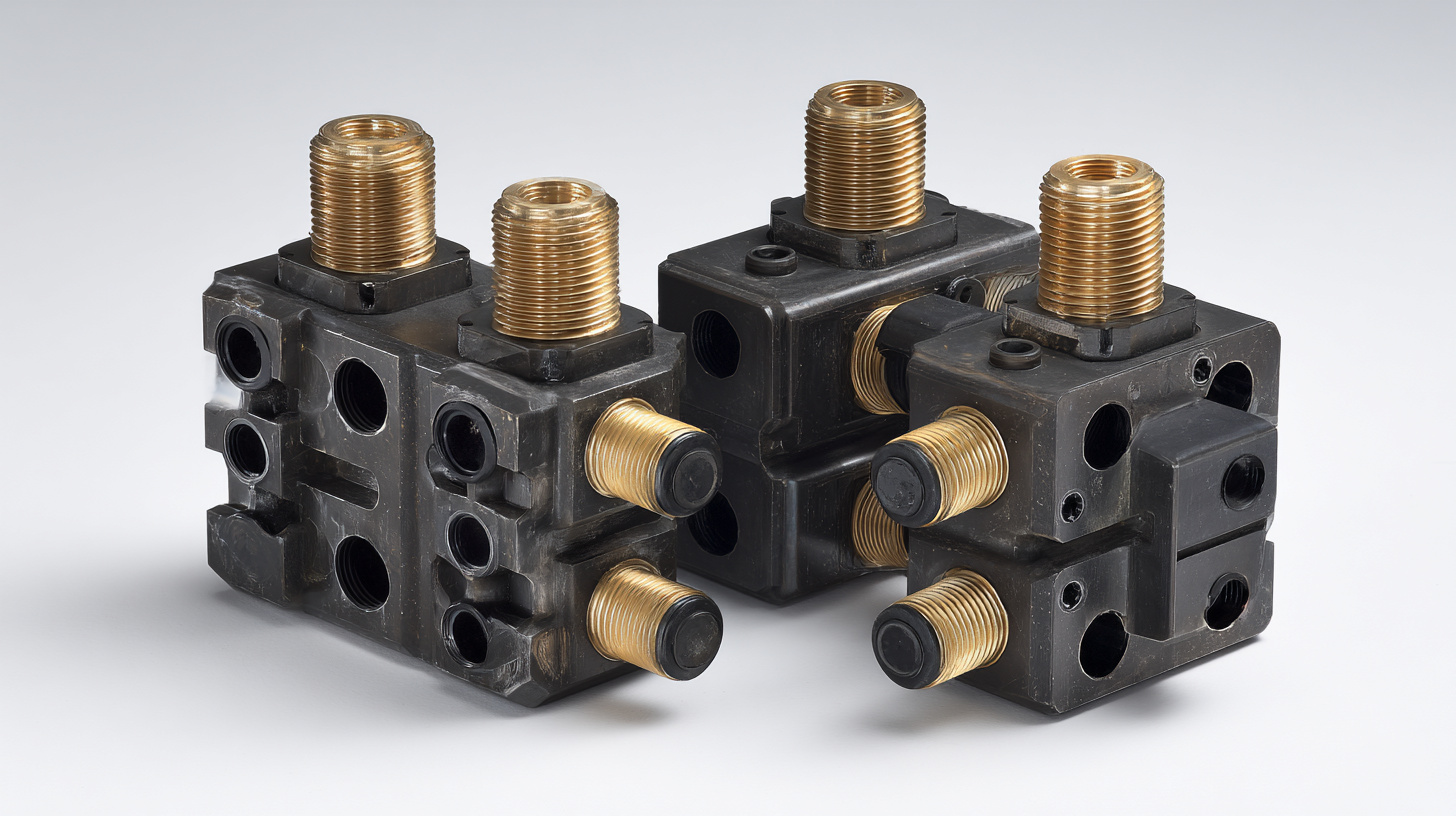

Primarily, logic element valves can be classified into various categories, including AND, OR, and NOT valves. Each type serves a unique function, allowing for precise control over pneumatic and hydraulic systems, which are vital in many industrial applications.

AND valves require multiple input signals to activate, ensuring that a specific condition must be met before the flow occurs. This type is beneficial in safety-critical systems where redundancy is key. Conversely, OR valves allow for a single input to control flow, enabling flexibility in system design and operation. Meanwhile, NOT valves invert input signals, providing control mechanisms that can shut off or redirect flow based on specific conditions. By understanding the distinct functions of these logic element valves, engineers and procurement specialists can better identify the right components that align with their operational requirements, enhancing both reliability and performance in industrial environments.

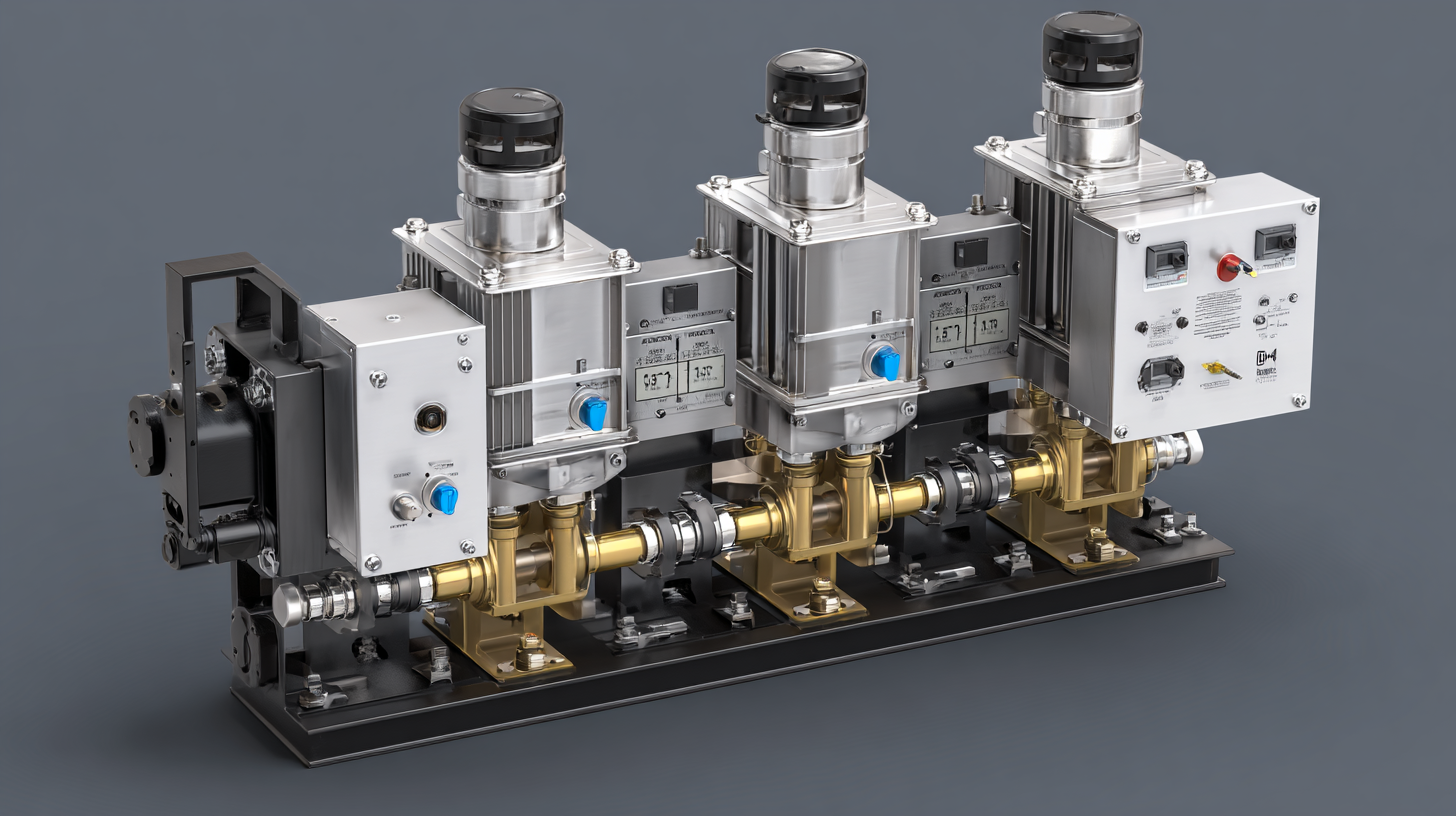

In the realm of industrial automation, logic element valves have become pivotal in optimizing processes. Case studies reveal how companies across various sectors successfully integrated these valves into their operations, leading to significant efficiency gains. For instance, a manufacturing plant that struggled with erratic fluid flow saw a remarkable turnaround after installing logic element valves. These valves allowed for precise control, minimizing wastage and ensuring consistent supply to critical machinery.

Another compelling example comes from the food processing industry, where hygiene and reliability are paramount. A facility implemented logic element valves to streamline the cleaning process. These valves were programmed to automatically control the flow of cleaning agents, ensuring thorough sanitation without manual intervention. As a result, the plant not only improved its compliance with safety standards but also decreased downtime, thus boosting overall productivity.

These real-world implementations highlight the transformative potential of logic element valves, showcasing their role in enhancing operational efficiency and safety in industrial environments.

When it comes to sourcing logic element valves for industrial applications, maximizing efficiency is crucial. Recent studies show that companies leveraging advanced technologies like deep learning (DL) and machine learning (ML) in supply chain management (SCM) can significantly enhance their procurement processes. For instance, organizations utilizing these technologies report up to a 20% reduction in sourcing costs and a notable improvement in supplier performance.

Tip 1: Utilize Data Analytics

Incorporating data analytics into your sourcing strategy allows you to make informed decisions based on real-time data and predictive insights. This not only aids in selecting the right suppliers but also enhances inventory control, ensuring that you have the necessary materials on hand without excess stock.

Tip 2: Foster Supplier Relationships

Building strong relationships with suppliers can lead to better negotiation outcomes and improved quality of service. Engaging in open communication and collaborative planning can help create a more resilient supply chain, reducing lead times and increasing overall operational efficiency.

By actively implementing such strategies, businesses can ensure they are sourcing the optimal logic element valves tailored to their specific industrial needs.

The future of logic element valve technology is poised for significant transformation, driven by advancements in digital manufacturing and the urgent need for sustainable practices. With industries increasingly focused on reducing environmental impact, there is a growing emphasis on integrating high-integrity pressure protection systems. The market for these systems is expanding, with recent reports indicating substantial growth spurred by initiatives to minimize gas flaring and venting, which are critical in oil and gas production. In fact, a significant proportion of gas flaring occurs globally, prompting regulatory and technological innovations aimed at mitigating these environmental footprints.

Furthermore, the rapid digital transformation within manufacturing is reshaping the landscape for valve technologies. Reports highlight the necessity for smart and adaptive solutions that can enhance operational efficiency and address challenges posed by traditional manufacturing methods. The introduction of 4D printing technologies, which leverage shape-changing materials, is one such innovation that could redefine how logic element valves are designed and produced. This evolution not only aligns with sustainability goals but also supports the industry’s shift toward more integrated and automated manufacturing processes. As these trends unfold, stakeholders must remain vigilant and adaptable to leverage the myriad opportunities that enhanced logic element valve technologies will bring.