In the ever-evolving landscape of industrial automation, the choice of components can significantly impact system performance and efficiency. Among these critical components are Logic Element Valves, which play a vital role in controlling fluid flow and enhancing system responsiveness. This blog aims to provide a comprehensive comparison of the efficiency and applications of Logic Element Valves, highlighting their unique designs and operational characteristics.

By examining various types of Logic Element Valves, we will explore how their specific functionalities can be leveraged to optimize process performance across different industries. Whether you are an engineer seeking to improve operational efficiency or a decision-maker evaluating component choices, this checklist-style blog will equip you with essential insights and practical considerations to guide your decisions regarding Logic Element Valves.

Join us as we delve into the intricacies and advantages of these pivotal components.

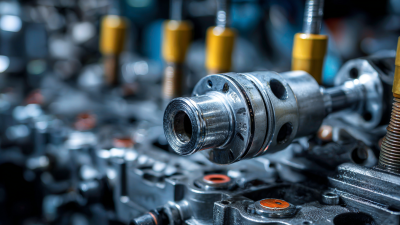

Logic element valves play a crucial role in various industrial applications, thanks to their unique types and functions. These valves, categorized mainly into AND, OR, NOT, and NAND types, facilitate logical operations in fluid control systems. For instance, AND valves require multiple conditions to trigger flow, making them ideal for applications where safety and precision are paramount. According to a recent report from the International Society for Automation, the use of logic element valves in automated processes can increase operational efficiency by up to 30%, thereby reducing energy consumption and operational costs.

In addition to efficiency, understanding the specific functions of these valves is essential for optimizing their use in industries ranging from manufacturing to environmental systems. A study published in the Journal of Fluid Engineering highlights that incorporating logic element valves into control systems not only streamlines processes but also enhances reliability, ensuring that systems operate smoothly under varying conditions. As industries increasingly seek automation and intelligent systems, the demand for specialized logic element valves is anticipated to grow significantly, aligning with trends towards smarter, more efficient operations.

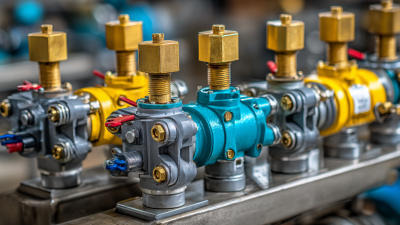

In the realm of industrial automation, the efficiency of logic element valves plays a crucial role in optimizing performance and reducing operational costs. A recent report by the International Society of Automation (ISA) highlights that the efficiency of logic element valves can vary significantly based on application and design, with some advanced models achieving energy savings of up to 20% compared to traditional valves. This efficiency gain is largely attributable to innovations in flow dynamics and controlling mechanisms, providing solutions that minimize energy consumption while maintaining high throughput rates.

Moreover, a comparative study conducted by the Fluid Power Institute found that logic element valves, particularly those employing proportional control technology, can enhance system responsiveness by 30%. This responsiveness not only improves process accuracy but also extends the lifespan of the entire hydraulic system. The report underlines the importance of selecting the appropriate logic element valve based on specific applications—such as pneumatic systems for packaging lines versus hydraulic applications in heavy machinery—highlighting that tailored solutions provide substantial operational advantages. As industries continue to seek more efficient systems, the data underscores the critical nature of evaluating valve efficiency in enhancing overall productivity.

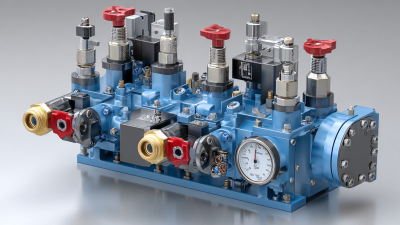

Logic Element Valves are pivotal components in various industries, providing precise control over fluid and gas flow by utilizing logical operations within pneumatic and hydraulic systems. In the automotive sector, these valves enhance system efficiency by optimizing the performance of pneumatic actuators, thereby reducing operational costs. According to a report by MarketsandMarkets, the global market for logic element valves is projected to reach USD 2.1 billion by 2025, highlighting their growing importance in automotive applications, particularly in fuel and hydraulic systems.

Logic Element Valves are pivotal components in various industries, providing precise control over fluid and gas flow by utilizing logical operations within pneumatic and hydraulic systems. In the automotive sector, these valves enhance system efficiency by optimizing the performance of pneumatic actuators, thereby reducing operational costs. According to a report by MarketsandMarkets, the global market for logic element valves is projected to reach USD 2.1 billion by 2025, highlighting their growing importance in automotive applications, particularly in fuel and hydraulic systems.

In the chemical processing industry, Logic Element Valves contribute significantly to safety and efficiency. They enable automatic shutdown and control operations, minimizing the risk of hazardous leaks or spills. A study conducted by Research and Markets indicates that the implementation of these valves can improve process reliability by up to 30%, making them essential for maintaining stringent safety standards. For industries such as oil and gas, where flow control consistency is critical, Logic Element Valves provide the necessary reliability and efficiency, ensuring that operations run smoothly while adhering to regulatory guidelines.

When selecting logic element valves, various factors come into play that can significantly influence their efficiency and suitability for specific applications. One critical aspect to consider is the architectural design of the system where these valves will operate. Just as the alignment of highways impacts vehicle speeds, the design of piping systems can affect the flow characteristics and operational efficiency of logic element valves. A well-designed system can enhance performance, reducing energy consumption and operational costs while ensuring reliability.

Additionally, the compatibility of materials used in the valve construction is essential. Environmental factors, akin to how habitats influence animal behaviors, are pivotal for the longevity and performance of valves in specific conditions. For instance, exposure to aggressive chemicals or varying temperatures can deteriorate valve materials, leading to failures or reduced efficiency. Understanding these interactions is crucial for making informed decisions in the selection process, ensuring that the chosen logic element valves not only fulfill operational requirements but also remain durable throughout their intended lifespan.

The landscape of logic element valve technology is on the brink of significant transformation, driven by advances in materials and automation. As industries strive for enhanced efficiency and sustainability, the evolution of these valves is pivotal. Innovative designs, such as miniature valves and smart actuators, are being engineered to meet the evolving demands of automation systems. These innovations not only optimize fluid control processes but also reduce energy consumption and maintenance costs, creating a more sustainable operational footprint.

Looking forward, the integration of Internet of Things (IoT) capabilities into logic element valves stands out as a promising trend. This connectivity allows for real-time monitoring and data analytics, enabling predictive maintenance and enhancing the overall performance of fluid systems. As industries increasingly prioritize digitalization, the adaptability of logic element valves to smart environments will be crucial. With ongoing research and development, we can expect to see enhanced performance metrics and smarter solutions that redefine efficiency in industrial processes.