In the ever-evolving landscape of industrial automation, the sourcing of componentry plays a critical role in enhancing operational efficiency and reliability. Pressure Compensated Throttle Valves have emerged as essential components across various sectors, including hydraulics and pneumatics, due to their ability to regulate fluid flow accurately regardless of pressure changes. According to a recent market analysis by Research and Markets, the global market for these valves is projected to reach $5.4 billion by 2025, driven by the rising demand for precision in fluid control technologies. As industries increasingly adopt smart manufacturing practices, the need for innovative sourcing strategies becomes paramount. This blog will explore a comprehensive checklist for identifying and procuring the best Pressure Compensated Throttle Valves globally, ensuring that businesses stay competitive and meet stringent operational standards.

The landscape of sourcing pressure compensated throttle valves is experiencing a radical transformation, driven by innovative technologies that streamline procurement processes while enhancing product quality. According to a recent report by Global Industry Analysts, the global market for throttle valves is projected to reach $12 billion by 2027, reflecting a compound annual growth rate (CAGR) of 5.8%. This growth is fueled by advancements in automation and IoT, which enable manufacturers to optimize their supply chains, reducing lead times and costs associated with traditional sourcing methods.

One of the most significant technological advancements is the integration of artificial intelligence (AI) in supplier selection and management. AI-driven analytics can assess supplier performance in real-time, helping companies identify the best options in the market. A study by McKinsey highlights that organizations employing AI in procurement can save up to 30% in costs. Additionally, blockchain technology is enhancing transparency and traceability in the supply chain, mitigating risks associated with sourcing from global markets. With these innovative approaches, companies can ensure they are sourcing high-quality pressure compensated throttle valves that meet stringent industry standards while remaining competitively priced.

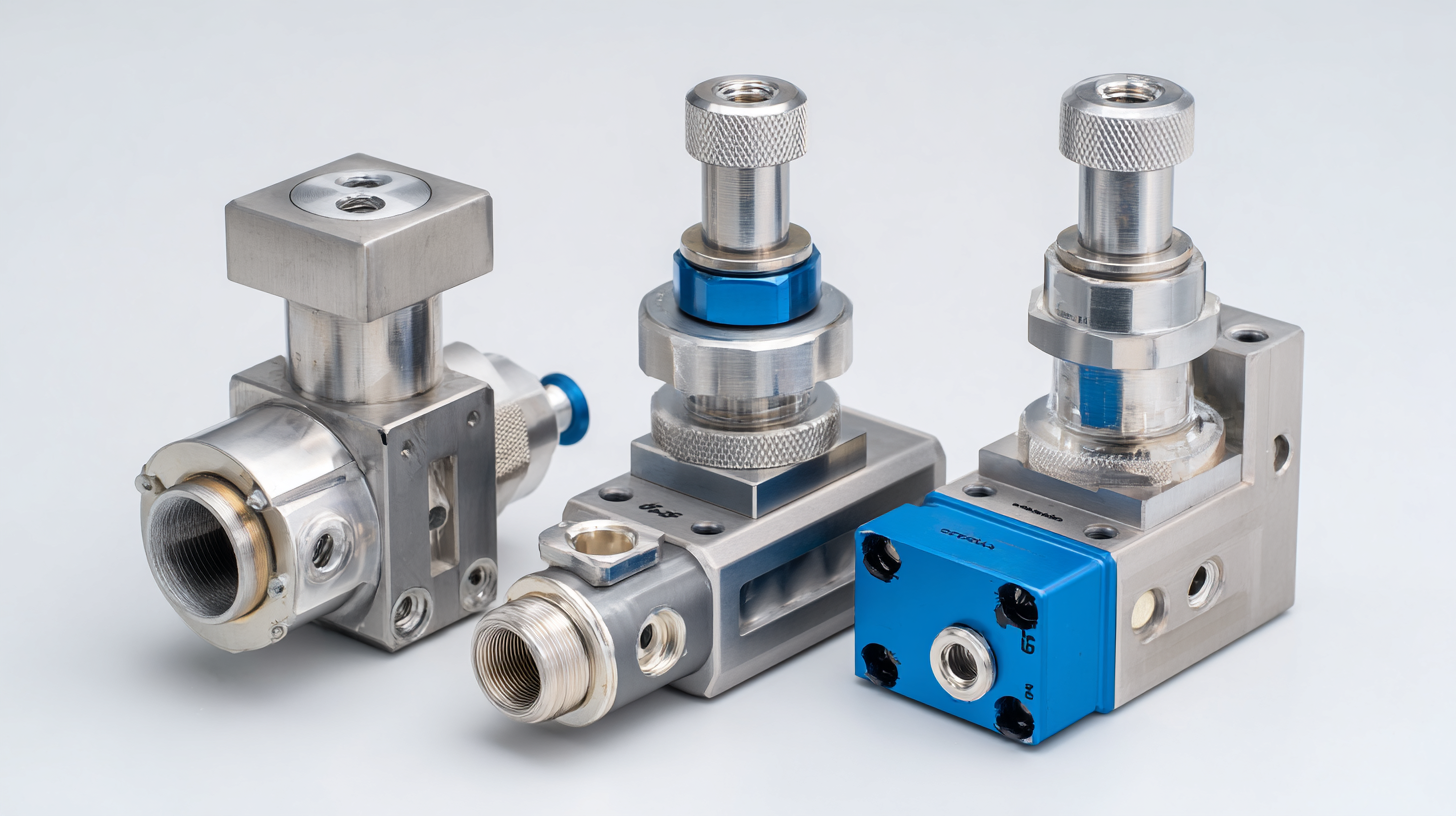

| Valve Type | Material | Pressure Range (Bar) | Flow Rate (L/min) | Application | Innovation Type |

|---|---|---|---|---|---|

| Digital Throttle Valve | Aluminum | 0-30 | 100 | Robotics | Smart Control |

| Analog Throttle Valve | Stainless Steel | 0-50 | 200 | Automotive | Pressure Regulation |

| Compact Throttle Valve | Plastic | 0-20 | 50 | Consumer Electronics | Eco-friendly Design |

| High-Precision Throttle Valve | Titanium | 0-100 | 300 | Aerospace | Advanced Materials |

In the evolving landscape of the global supply chain, innovative sourcing strategies are critical for companies aiming to find high-quality pressure compensated throttle valves. With the global supply chain analytics market projected to grow from $11.08 billion in 2025 to $32.71 billion by 2032 at a compound annual growth rate (CAGR) of 16.7%, the relevance of data analytics in sourcing cannot be overstated. By leveraging advanced analytics, companies can gain deeper insights into supplier performance, market trends, and inventory management, enabling more informed decision-making.

Data analytics enhances the sourcing of throttle valves by facilitating real-time tracking of global suppliers. It allows businesses to evaluate potential suppliers' reliability and quality more efficiently, reducing risks associated with sourcing. This analytical approach not only optimizes procurement processes but also helps in identifying emerging markets and opportunities. As industries increasingly rely on data-driven strategies, companies that effectively utilize analytics will be well-positioned to achieve competitive advantages in the sourcing of essential components like throttle valves.

This bar chart illustrates the sourcing distribution of pressure compensated throttle valves across different regions in 2023, highlighting the reliance on data analytics for optimal sourcing decisions.

The global supply chain landscape has undergone significant transformations, especially in the procurement of specialized components such as pressure compensated throttle valves. Current trends show a shift towards more localized sourcing strategies, driven by the need for resilience and quick response to market fluctuations. As manufacturers strive to mitigate risks associated with long-distance logistics, partnerships with regional suppliers have become increasingly popular. This not only allows for faster delivery times but also fosters communication and collaboration, which are crucial in optimizing valve performance and reducing lead times.

Moreover, digital technology is reshaping procurement practices within the valve industry. Companies are leveraging advanced analytics and supply chain management software to enhance visibility and streamline the decision-making process. By integrating data-driven insights, organizations can better anticipate demand shifts and adjust their sourcing strategies accordingly. This proactive approach is particularly important for pressure compensated valves, where precision and reliability are paramount. As these trends continue to evolve, companies that adopt innovative sourcing methods will be better positioned to meet the growing demands of various industries while ensuring consistent quality and performance.

In the competitive landscape of throttle valve sourcing, innovative strategies are pivotal for achieving cost-effectiveness and operational efficiency. A recent study by Research and Markets reported that the global throttle valve market is expected to reach $9.4 billion by 2028, growing at a CAGR of 4.5%. This growth highlights the necessity for sourcing approaches that not only focus on cost reduction but also on supplier reliability and technological advancements.

One successful sourcing strategy can be observed in a leading automotive manufacturer that implemented a dual-sourcing model for pressure compensated throttle valves. By partnering with suppliers across different geographies, the company minimized production risks and ensured a steady supply chain. Their internal analysis showed a reduction in lead times by 25%, while also enhancing flexibility to respond to fluctuating demands. Similarly, adopting advanced analytics in supplier assessment helped identify high-performing manufacturers who met stringent quality criteria, thereby reinforcing the company’s commitment to excellence in product performance and reliability. These case studies exemplify how strategic sourcing can drive growth and innovation within the throttle valve industry.

Emerging markets have become pivotal in the global sourcing dynamics for pressure compensated throttle valves, playing a significant role in shaping supply chains and driving innovation. Countries in Southeast Asia, Eastern Europe, and Africa are not only rich in resources but also offer competitive labor costs and growing manufacturing capabilities. As industries in these regions develop, they are increasingly catering to the demands of international markets, enabling companies to source high-quality components at lower prices. This shift allows manufacturers to enhance their product offerings while maintaining cost efficiency.

Emerging markets have become pivotal in the global sourcing dynamics for pressure compensated throttle valves, playing a significant role in shaping supply chains and driving innovation. Countries in Southeast Asia, Eastern Europe, and Africa are not only rich in resources but also offer competitive labor costs and growing manufacturing capabilities. As industries in these regions develop, they are increasingly catering to the demands of international markets, enabling companies to source high-quality components at lower prices. This shift allows manufacturers to enhance their product offerings while maintaining cost efficiency.

Moreover, these emerging markets are adopting advanced technologies and sustainable practices, further bolstering their appeal as sourcing hubs for throttle valves. Investment in research and development is on the rise, leading to significant improvements in engineering and production processes. As a result, companies can find suppliers who not only provide cost-effective solutions but also uphold quality standards. By tapping into these dynamic markets, businesses can gain a competitive edge, ensuring they are well-positioned to meet the evolving needs of their customers globally.