Choosing the right Directional Control Valves is crucial for ensuring optimal performance in hydraulic and pneumatic systems. With a myriad of options available in the market, making an informed choice can be challenging yet essential for the efficiency and reliability of your operations. This ultimate guide aims to dispel the complexities surrounding Directional Control Valves, providing you with the knowledge needed to select the ideal valves for your specific applications. By understanding the various types, functionalities, and factors influencing your decision, you will be better equipped to enhance system performance, reduce downtime, and achieve seamless control over fluid dynamics. Whether you’re a seasoned engineer or a newcomer to the field, this comprehensive resource will serve as your go-to reference for selecting Directional Control Valves that align with your operational goals.

When selecting directional control valves for hydraulic systems, several key factors must be carefully considered to ensure optimal performance. Firstly, understanding the flow requirements is essential. This encompasses the maximum flow rates and the specific patterns of direction required for your application. Choosing a valve that can handle the peak flow without causing excessive pressure drops or turbulence is crucial for maintaining system efficiency.

Another important aspect is the compatibility of the valve materials with the working fluids. If the valve materials are not suitable, it can lead to corrosion and decreased operational lifespan, compromising the entire system. Additionally, consider the actuator type; whether it’s manual, pneumatic, or hydraulic can significantly influence the responsiveness and performance of the valve. The design and configuration, such as the number of ports and positions, should align with the specific needs of your system to facilitate seamless operation throughout its processes. By paying attention to these factors, you can enhance the reliability and safety of your hydraulic applications.

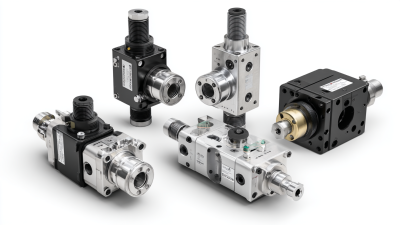

Directional control valves are essential components in hydraulic and pneumatic systems, allowing for precise control over fluid flow and direction. Understanding the different types of directional control valves is crucial for selecting the right one for your application. The most common types include spool valves, poppet valves, and rotary valves. Each type operates differently and is suited for specific use cases. For instance, spool valves are widely used in applications requiring simultaneous flow in multiple directions, while poppet valves are ideal for high-pressure systems where quick actuation is necessary.

When considering applications, it’s important to evaluate factors such as flow rate, pressure, and the required response time. Spool valves can be found in industrial machinery and mobile equipment, providing flexibility in controlling the movement of actuators and cylinders. On the other hand, poppet valves are favored in automotive applications and hydraulic lifts due to their rapid operation and reliability under high pressure. Additionally, rotary valves, which control flow through a rotating disc, are well-suited for applications needing variable flow rates. By understanding these different types, you can select the most appropriate directional control valve to optimize system performance and efficiency.

| Valve Type | Operating Principle | Applications | Port Configuration | Typical Size Range |

|---|---|---|---|---|

| 2/2 Way Valve | Direct-acting | On/Off control, fluid isolation | 2 ports | 1/8" to 2" |

| 3/2 Way Valve | Pneumatic or hydraulic | Actuator control, fluid direction | 3 ports | 1/8" to 3" |

| 4/2 Way Valve | Mechanically or electrically-operated | Hydraulic cylinders actuation | 4 ports | 1/4" to 4" |

| 5/2 Way Valve | Solenoid-operated | Double acting cylinder control | 5 ports | 1/4" to 3" |

When selecting directional control valves, understanding how flow direction and pressure influence valve performance is crucial for system efficiency. The flow direction determines the path that the hydraulic fluid takes, which affects the operation of the entire hydraulic system. Ensuring that the valve aligns with the intended flow direction is essential for preventing potential system malfunctions.

Tips: Always check the manufacturer specifications for flow direction indications. Install directional control valves with proper orientation to ensure maximum performance and reliability.

Pressure is another critical aspect that significantly impacts valve operation. The pressure rating of a valve must match the system's operating pressure to avoid failures. Inadequate pressure compatibility can lead to leaks or valve sticking, compromising overall system performance.

Tips: Regularly monitor system pressure to ensure it does not exceed the valve’s rating. Consider using pressure relief valves to protect against unexpected pressure surges.

When it comes to the installation and maintenance of directional control valves, adhering to best practices is crucial for ensuring optimal system performance. According to a report by the National Fluid Power Association (NFPA), improper installation accounts for nearly 30% of valve failures in hydraulic systems. This underscores the importance of following manufacturer guidelines and ensuring that all components are compatible and correctly aligned during installation. Additionally, periodic inspections can help identify potential issues before they escalate, significantly reducing downtime and maintenance costs.

Routine maintenance of directional control valves is equally essential. A study from the International Society for Automation indicates that regular maintenance can enhance valve reliability by up to 40%. This includes flushing the system to remove contaminants, checking for leaks, and ensuring that seals and actuators are functioning properly. By incorporating predictive maintenance schedules that utilize data analytics to anticipate wear and failure, operators can further enhance the longevity and reliability of their hydraulic systems. Leveraging such practices not only maximizes operational efficiency but also minimizes unexpected failures.

Directional control valves are critical components in hydraulic systems, influencing the efficiency and reliability of machinery operations. However, they often encounter common issues that can compromise overall system performance. According to the Hydraulic Institute, nearly 30% of mechanical failures in hydraulic systems are attributed to valve-related problems. These issues can stem from contamination, improper installation, or inadequate maintenance.

One frequent problem is internal leakage, which can lead to decreased system pressure and efficiency. A study published in the Journal of Fluid Power Research highlights that even minor leakage in directional control valves can reduce hydraulic effectiveness by up to 15%. Regular diagnostics and maintenance checks are necessary to identify and address these leaks early. Additionally, the selection of the appropriate valve type, whether spool, poppet, or rotary control valves, plays a significant role in minimizing operational failures.

Furthermore, electrical malfunctions in electro-hydraulic valves may pose challenges, often caused by electromagnetic interference or improper wiring. The International Fluid Power Society reports that approximately 18% of electronic component failures are linked to such issues. Ensuring proper installation practices and utilizing robust components can mitigate these risks, ensuring that directional control valves contribute positively to system performance.

This bar chart illustrates the performance metrics of directional control valves, highlighting key dimensions such as flow rate, pressure drop, response time, and power consumption. Understanding these parameters is essential for optimal system performance and troubleshooting common issues.