In recent years, the Chinese manufacturing sector has witnessed a remarkable transformation, particularly in the production of Load Control Valves, which play a crucial role in hydraulic and pneumatic systems.

According to a report by MarketsandMarkets, the global load control valves market is projected to reach USD 7.2 billion by 2025, growing at a CAGR of 5.3%. This surge is driven by the increasing demand for automation across industries such as construction, mining, and agriculture, where efficient load management is essential for operational effectiveness.

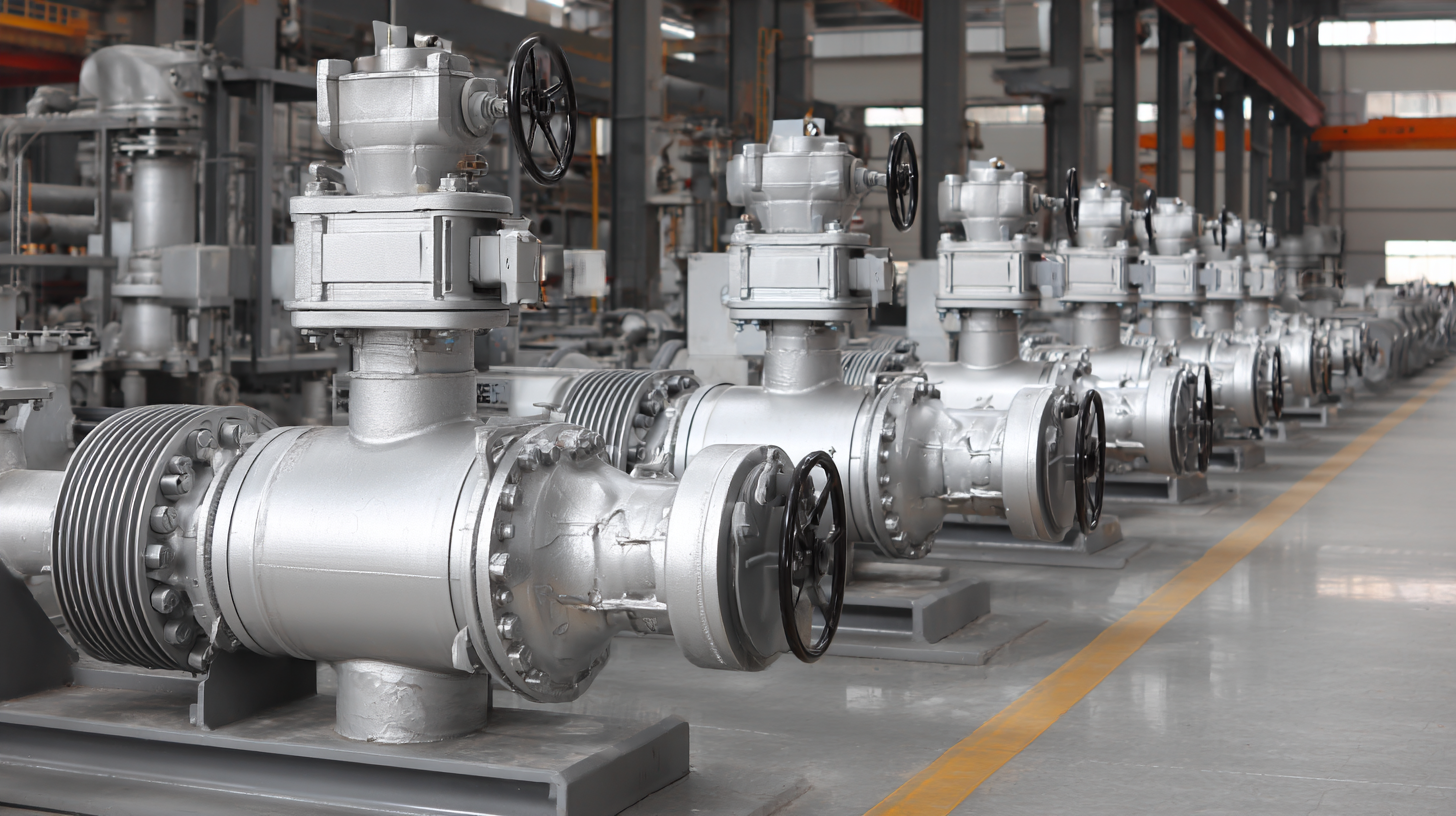

Recognized for their innovation and high-quality standards, Chinese manufacturers have emerged as key players on the global stage, offering technologically advanced solutions that meet international specifications. As a result, Load Control Valves produced in China are gaining significant traction, underscoring the country's commitment to excellence in this critical sector.

According to a report by MarketsandMarkets, the global load control valves market is projected to reach USD 7.2 billion by 2025, growing at a CAGR of 5.3%. This surge is driven by the increasing demand for automation across industries such as construction, mining, and agriculture, where efficient load management is essential for operational effectiveness.

Recognized for their innovation and high-quality standards, Chinese manufacturers have emerged as key players on the global stage, offering technologically advanced solutions that meet international specifications. As a result, Load Control Valves produced in China are gaining significant traction, underscoring the country's commitment to excellence in this critical sector.

Chinese manufacturing has made significant breakthroughs in load control valve technology, leading to innovations that are reshaping global standards. Companies in China are investing heavily in research and development, resulting in advanced designs that enhance efficiency and performance. These technological advancements not only improve the reliability of hydraulic systems but also contribute to energy savings and reduced operational costs.

Tip: When selecting a load control valve, consider the specific application requirements such as flow rate and pressure levels. This ensures optimal performance and longevity of the system.

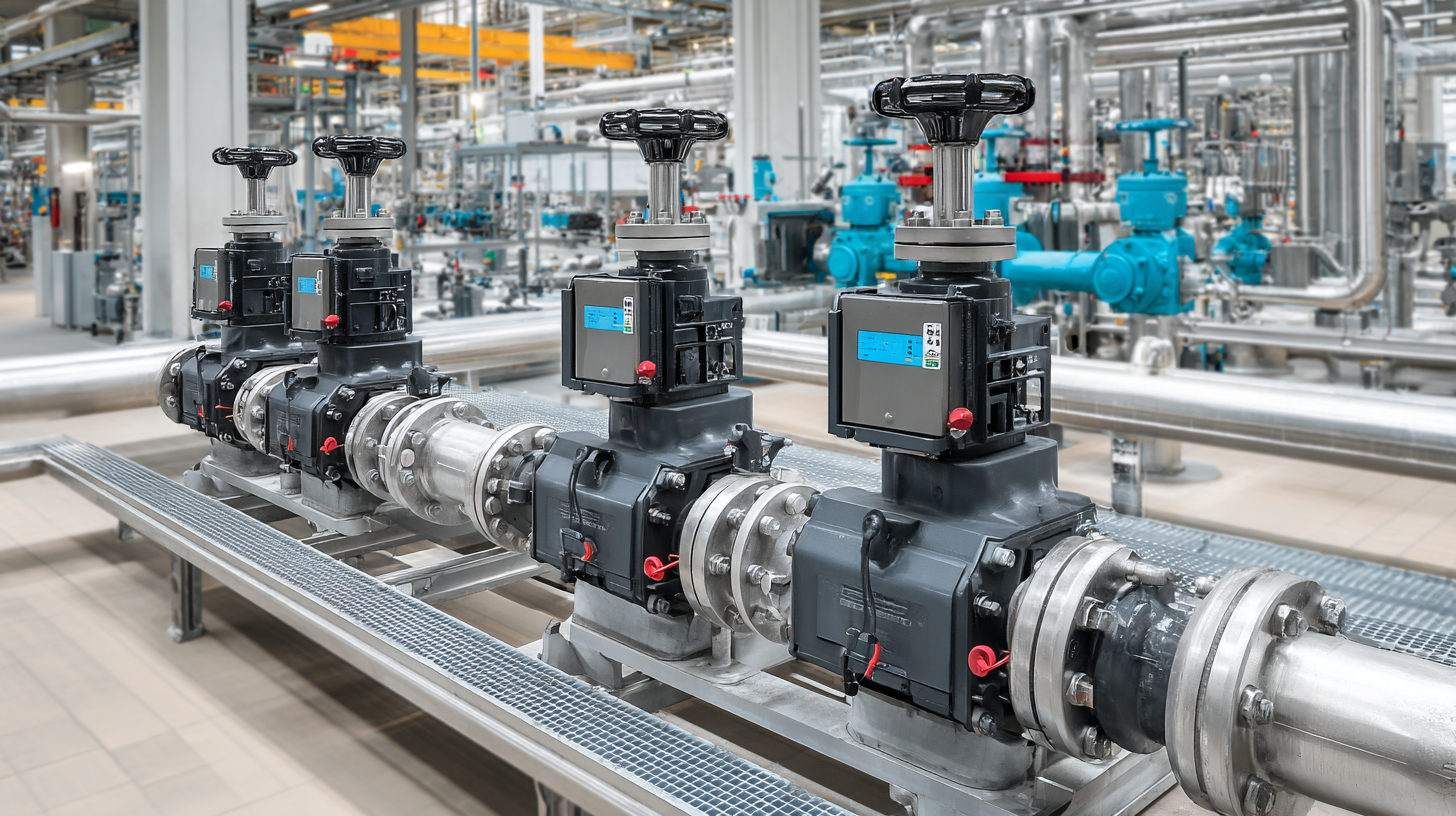

Moreover, Chinese manufacturers are adopting smart manufacturing techniques and leveraging automation to streamline production processes. This shift not only increases output but also enhances the precision of load control valves. As a result, customers worldwide are increasingly recognizing the quality and dependability of these products, positioning Chinese manufacturers as leaders in the global market.

Tip: Regular maintenance and inspection of load control valves can prevent costly breakdowns and extend their lifespan. Establish a routine check to ensure they are functioning at their best.

| Dimension | Details |

|---|---|

| Production Volume (Units/Year) | 500,000 |

| Market Share (%) | 25% |

| Research & Development Investment (Million USD) | 30 |

| Export Markets | North America, Europe, Asia Pacific |

| Technology Innovations | Smart Load Control, Energy Efficiency Solutions |

| Certification Standards | ISO 9001, CE, RoHS |

The global market for load control valves is experiencing significant growth, driven by increasing demand across various industries. According to a report by Market Research Future, the load control valve market is projected to reach USD 4 billion by 2025, growing at a compound annual growth rate (CAGR) of approximately 6% from 2020. This surge is largely attributed to the rising automation in manufacturing processes and the need for energy efficiency, particularly in industrial applications where precise flow control is essential.

Additionally, the construction and agricultural sectors are becoming key players in this demand trajectory. The increasing adoption of advanced machinery in construction projects, combined with the push for sustainable agricultural practices, has enhanced the need for sophisticated load control systems. A recent study by Technavio indicates that the agricultural segment alone is expected to contribute over 25% to the total market share by 2025, signifying a robust opportunity for manufacturers, especially those in China, who are gaining global recognition for their high-quality products. With these trends in play, the landscape for load control valves is set for remarkable transformation in the coming years.

In recent years, China's load control valve sector has emerged as a significant player on the global stage, with key industry players investing heavily in technology and innovation. According to a recent report by MarketsandMarkets, the global load control valve market is expected to grow from USD 4.2 billion in 2021 to USD 5.9 billion by 2026, at a CAGR of 7.1%. This growth reflects the increased demand for reliable and efficient fluid control solutions in various industries, including automotive, aerospace, and manufacturing.

Leading companies in China's load control valve market, such as Casappa China and Huade, have gained recognition for their robust product offerings and cutting-edge manufacturing practices. For instance, Casappa China has leveraged advanced automation in its production lines, resulting in a threefold increase in output capacity over the last five years. Furthermore, Huade's commitment to quality and compliance with international standards has allowed it to secure contracts with major global firms, reinforcing China's reputation as a hub for manufacturing excellence in this specialized sector.

The competitive landscape is also being shaped by emerging startups that focus on niche markets and innovative solutions. As these companies continue to push the boundaries of traditional manufacturing, they are likely to present significant challenges and opportunities for established players, further amplifying the global impact of China's load control valve industry.

Chinese manufacturing has witnessed a remarkable transformation, especially in the production of load control valves. Innovative manufacturing techniques are at the forefront of this evolution, significantly enhancing valve performance and boosting global competitiveness. Techniques such as advanced robotics, precision machining, and smart manufacturing processes enable Chinese manufacturers to produce high-quality valves that meet stringent international standards. The integration of cutting-edge technologies ensures consistent performance and reliability in various industrial applications.

Chinese manufacturing has witnessed a remarkable transformation, especially in the production of load control valves. Innovative manufacturing techniques are at the forefront of this evolution, significantly enhancing valve performance and boosting global competitiveness. Techniques such as advanced robotics, precision machining, and smart manufacturing processes enable Chinese manufacturers to produce high-quality valves that meet stringent international standards. The integration of cutting-edge technologies ensures consistent performance and reliability in various industrial applications.

Tip: Regularly assess your valve specifications and performance needs to ensure compatibility with the latest manufacturing innovations. As valve technologies evolve, staying informed about the latest advancements can help producers and users select the best products for their specific applications.

Moreover, continuous improvement in quality control measures is a key factor driving excellence in valve production. By adapting lean manufacturing principles and embracing quality management systems, Chinese manufacturers can minimize waste and optimize production efficiency. This not only enhances the performance of their valves but also fosters a culture of innovation that can lead to new product developments.

Tip: Implement a feedback loop from end-users to identify performance gaps and areas for improvement in valve design and functionality. Engaging with customers can provide invaluable insights that lead to product enhancements and ultimately elevate overall performance and satisfaction.

The load control valve (LCV) market has seen a notable shift towards sustainability, aligning with global environmental goals. According to a recent industry report by ResearchAndMarkets, the global load control valve market is projected to reach USD 13.5 billion by 2027, with a significant emphasis on eco-friendly production methods. Manufacturers, especially in China, are adopting innovative technologies to minimize waste during the production process, utilize recyclable materials, and enhance energy efficiency. This shift not only meets the increasing regulatory demands from various countries but also aligns with consumer expectations for more sustainable products.

In a survey conducted by the International Society of Automation (ISA), over 70% of industry leaders indicated that integrating sustainability into their manufacturing processes is a top priority. Chinese manufacturers leading the LCV sector have embraced this trend by investing in advanced automation and data analytics, optimizing their production lines to reduce carbon footprints. This approach not only enhances their competitive edge globally but also positions them as exemplars of sustainable practices in an industry that has often been scrutinized for its environmental impact. As a result, these companies are gaining recognition and setting new standards for excellence in load control valve production, paving the way for a greener future.