As industries increasingly rely on hydraulic systems for efficiency and performance, selecting the right components becomes paramount. In 2023, the market for Hydraulic Threaded Cartridge Valves has seen significant growth, projected to reach over $2 billion globally according to the latest market research reports. These valves are essential for controlling fluid power in various applications, from construction to manufacturing. However, the effectiveness of these systems hinges on the quality of the valves used.

This blog aims to provide an essential checklist for choosing the best Hydraulic Threaded Cartridge Valves, emphasizing the importance of sourcing from reputable suppliers. We will explore critical factors such as valve type, material quality, and supplier reliability to ensure optimal performance and longevity of hydraulic systems. Understanding these elements is vital for industry professionals aiming to enhance operational efficiency and minimize downtime.

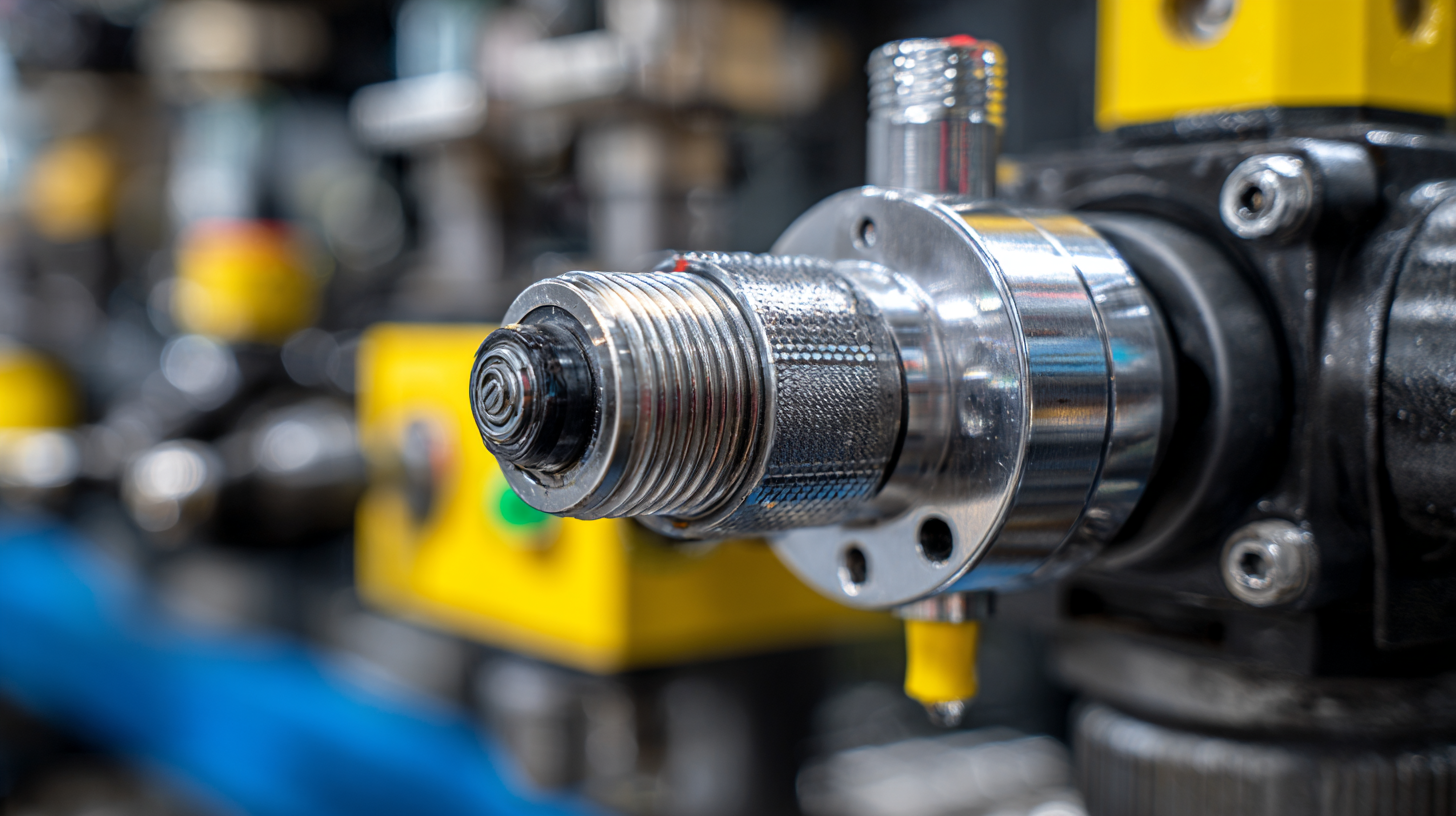

When selecting hydraulic threaded cartridge valves, understanding key specifications and parameters is crucial for optimal performance. These valves are typically measured by their flow rate, pressure rating, and port sizes. According to the Fluid Power Society, the flow rate in hydraulic systems is often expressed in gallons per minute (GPM) and can significantly impact efficiency. Choosing valves that can handle the required flow rate while maintaining consistent pressure levels is essential for preventing system failures and ensuring smooth operation.

Another important factor is the pressure rating, which quantifies the maximum pressure the valve can withstand. Recent studies indicate that industries using hydraulic systems are increasingly operating at higher pressures, with some applications requiring ratings exceeding 5,000 PSI. As noted in the Hydraulic Institute's annual report, failing to choose a valve with adequate pressure rating can lead to catastrophic failures, resulting in costly downtime. Additionally, the port size must match the existing system to facilitate seamless installation and operation. Ensuring compatibility across these specifications can lead to enhanced reliability and increased system lifespan, making thorough research a necessity in the selection process.

The hydraulic cartridge valves market is experiencing significant growth in 2023, driven by advancements in technology and increasing demand across various industries. The adoption of hydraulic systems in sectors such as construction, agriculture, and manufacturing has led to an escalation in the use of cartridge valves, which are known for their compact design and high reliability. These valves optimize system efficiency by providing precise control over fluid flow and pressure, thus enhancing overall productivity.

Furthermore, the push for sustainability and energy efficiency has prompted manufacturers to innovate and improve their products. As companies seek to reduce operational costs, the hydraulic cartridge valves they choose must meet stringent performance standards while also contributing to lower energy consumption. The growing emphasis on automation and smart technologies in hydraulic systems is also influencing purchasing decisions, encouraging a shift towards more sophisticated valve designs equipped with advanced control features. As the market continues to evolve, industry players must stay informed about these trends to make the best decisions when selecting hydraulic threaded cartridge valves.

When selecting hydraulic threaded cartridge valves, understanding the performance metrics is crucial. Look for valves that exhibit a low pressure drop, as this enhances the efficiency of your hydraulic system. Additionally, consider the flow rate and responsiveness of the valves—optimal performance often comes from valves that can adjust swiftly to changing conditions without compromising stability.

Tip: Always check the manufacturer's specifications for the maximum flow and pressure ratings of the cartridge valves. Choosing a valve with a higher flow capacity than necessary can lead to system inefficiencies and increased wear and tear over time.

Another key feature is the valve's material and sealing technology. High-quality materials will extend the life of the valve, while effective sealing ensures minimal leakage and reduces maintenance costs. The choice of seals should match the application's temperature and fluid type to achieve the best performance.

Tip: Investing in valves with advanced sealing technologies not only enhances durability but can also prevent potential operational failures, saving you time and money in the long run. Always prioritize quality over price for better long-term results.

When selecting hydraulic threaded cartridge valves, the material composition plays a pivotal role in determining not only the performance but also the longevity of the valve. Different materials offer varying levels of resistance to wear, corrosion, and deformation under pressure. For instance, stainless steel valves are known for their durability and resistance to rust, making them ideal for applications in harsh environments. On the other hand, brass valves, while less expensive, may not withstand high pressures as effectively, which could lead to premature failure.

Choosing the right material also affects maintenance requirements and overall cost-effectiveness of your hydraulic system. Valves made from high-quality materials may have a higher upfront cost but can save significant money in the long run due to reduced maintenance and replacement needs. Additionally, understanding the specific requirements of your application, such as temperature fluctuations and exposure to chemicals, will guide you in selecting a valve material that ensures optimal performance and extended lifespan. Therefore, prioritizing the valve composition is crucial for enhancing system efficiency and reliability.

When budgeting for quality hydraulic threaded cartridge valves in 2023, it’s crucial to conduct a thorough cost analysis. The initial purchase price may be enticing, but consider the long-term implications of your investment. Quality valves may have a higher upfront cost, but they can significantly reduce maintenance costs and replacement frequency over time. Make sure to account for all potential expenses, including installation and future maintenance.

Tip: Always compare the total lifecycle costs of different valve options. This includes the purchase price, installation fees, and expected operational longevity. Reach out to suppliers for transparent pricing, and inquire about warranty packages or service agreements that could save costs in the long run.

Additionally, prioritize suppliers that offer comprehensive support and resources. While you may find lower prices elsewhere, the value of after-sales support can far outweigh saving a few dollars upfront. A reliable supplier will assist you with installation guidance and technical support, minimizing downtime and maximizing efficiency.

Tip: Invest time in researching various suppliers and reading customer reviews. A well-supported investment not only ensures you get high-quality valves but also enhances the overall reliability of your hydraulic systems.

| Criteria | Importance Level | Estimated Cost (USD) | Recommended Features |

|---|---|---|---|

| Material Quality | High | $150 - $300 | Corrosion resistance, durability |

| Flow Rate | Medium | $100 - $200 | High efficiency, adjustable settings |

| Pressure Rating | High | $200 - $400 | Compatible with high-pressure systems |

| Size Compatibility | Medium | $50 - $150 | Available in multiple sizes |

| Warranty and Support | High | $0 - $100 | Comprehensive support and warranty |

| Installation Requirements | Medium | $20 - $50 | Easy installation or professional setup |