When selecting the best Auto Parts Hydraulic Valve for your vehicle, understanding the intricate technical specifications is crucial. According to a recent industry report by Grand View Research, the global automotive parts market is projected to reach $1 trillion by 2025, with a significant emphasis on hydraulic systems due to their efficiency and reliability. Hydraulic valves, being integral to this system, regulate fluid flow and pressure, which directly affects engine performance and vehicle safety. A study from the Society of Automotive Engineers highlights that the proper choice of hydraulic components can enhance vehicle operational efficiency by up to 30%. This underscores the necessity for a comprehensive checklist that not only evaluates the functional compatibility with your vehicle but also aligns with the latest technological advancements in the automotive sector.

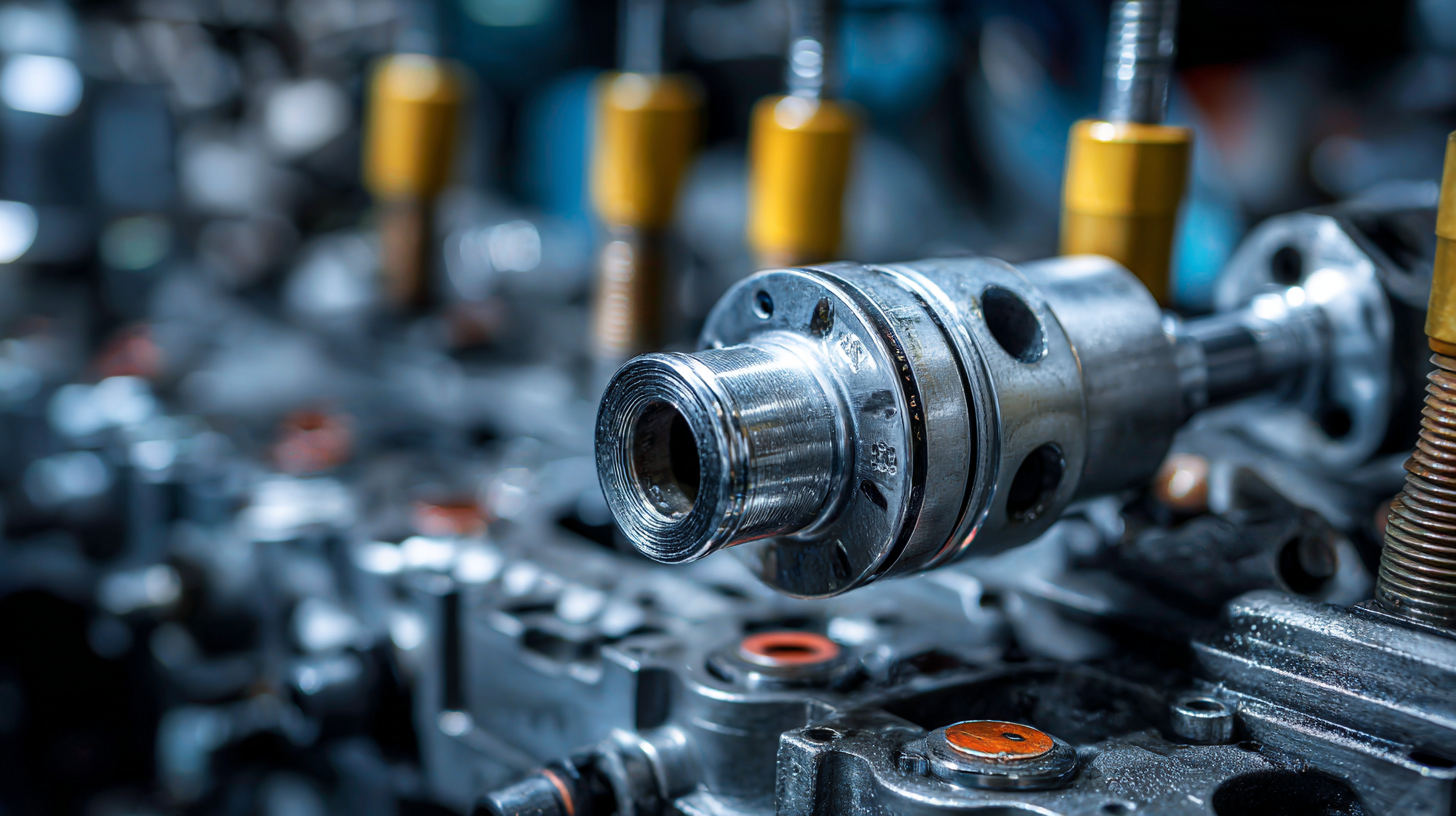

Hydraulic valves play a crucial role in controlling fluid flow within automotive systems, which directly impacts the vehicle's performance and safety. There are several types of hydraulic valves, each designed for specific applications. For instance, directional control valves are essential for managing the path of hydraulic fluid, allowing operators to direct flow to multiple actuators. These valves are commonly used in systems that require reversible motion, such as hydraulic lifts and steering mechanisms.

Another important type is pressure control valves, which regulate system pressure to prevent overloading and ensure optimal performance. These valves are often employed in braking systems and hydraulic power steering, where maintaining precise pressure levels is vital for safety and control. Additionally, flow control valves manage the speed of hydraulic actuators, essential in applications like automatic transmissions and lifting equipment. Understanding the unique purposes and applications of these hydraulic valves helps vehicle owners make informed decisions when choosing auto parts, ultimately enhancing the efficiency and longevity of their vehicles.

When selecting the best hydraulic valve for your vehicle, understanding the key features is essential to ensure optimal performance and reliability. One of the most critical characteristics of a hydraulic valve is its response time. A quick response ensures that the valve can handle variations in pressure efficiently, providing smooth control over hydraulic functions. Additionally, valves with durable materials can withstand harsh environments and high pressures, reducing the likelihood of failure during operation.

Another important aspect to consider is the valve's flow control capabilities. A well-designed hydraulic valve should allow for precise regulation of fluid flow, which is vital in applications demanding accuracy, such as in heavy machinery or performance vehicles. Compatibility with your engine's specifications is equally crucial; valves should seamlessly integrate with existing hydraulic systems without causing significant modifications. Ultimately, focusing on these key features will help you choose a hydraulic valve that enhances your vehicle's performance and longevity.

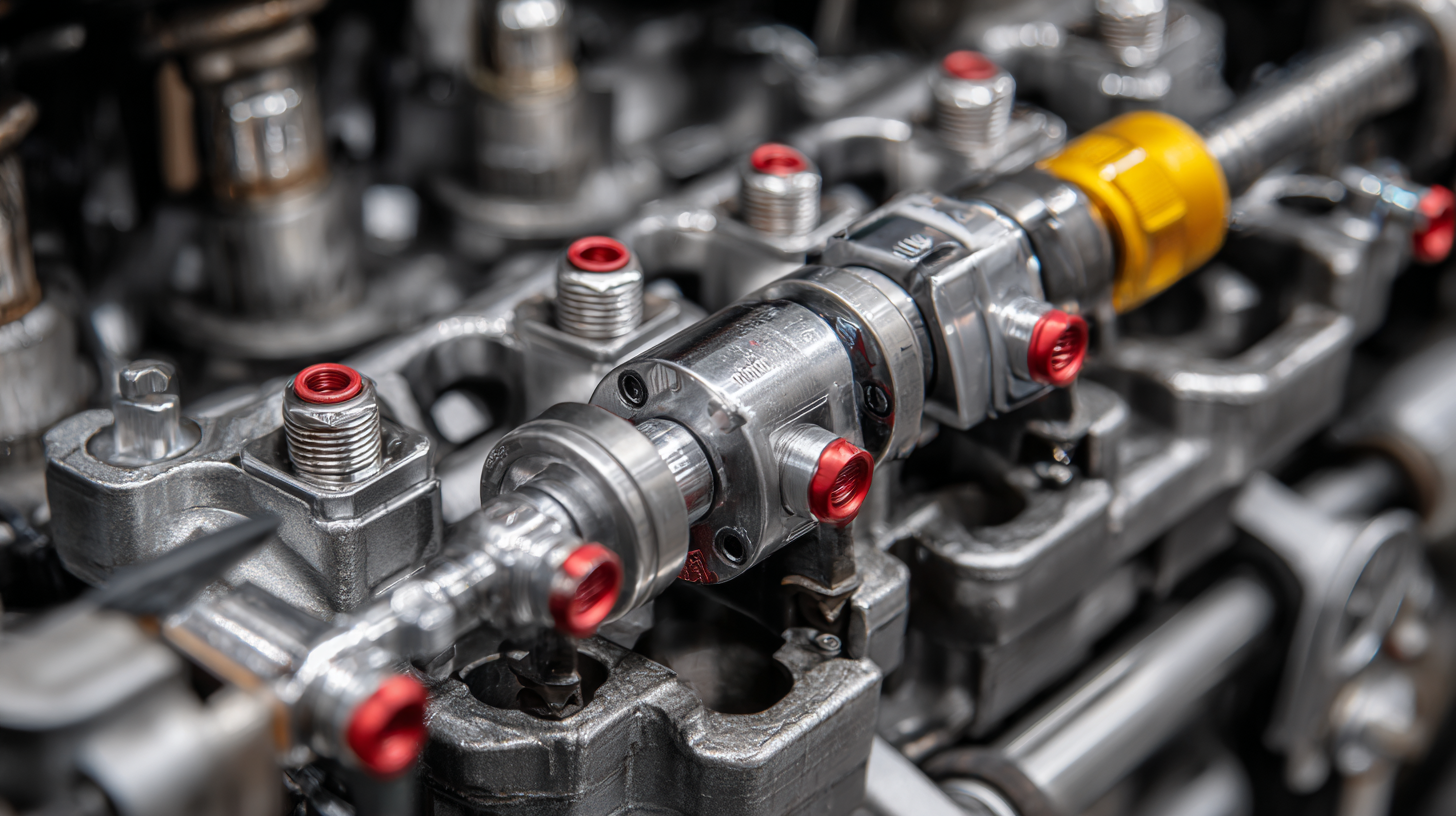

When choosing the right hydraulic valve for your vehicle, it's crucial to consider several key factors to ensure optimal performance. One of the most significant considerations is the compatibility of the hydraulic valve with your existing system. Industry reports indicate that improper compatibility can lead to decreased efficiency and increased wear, which may reduce the lifespan of the vehicle's components. Furthermore, factors such as flow rate, pressure rating, and valve type must align with your vehicle’s specifications to guarantee reliable operation.

When choosing the right hydraulic valve for your vehicle, it's crucial to consider several key factors to ensure optimal performance. One of the most significant considerations is the compatibility of the hydraulic valve with your existing system. Industry reports indicate that improper compatibility can lead to decreased efficiency and increased wear, which may reduce the lifespan of the vehicle's components. Furthermore, factors such as flow rate, pressure rating, and valve type must align with your vehicle’s specifications to guarantee reliable operation.

Recent advancements in the field also emphasize the growing role of pneumatic controls in hydraulic systems, presenting a safer and more cost-effective solution for various applications. Studies have shown that integrating pneumatic technology can enhance the performance of hydraulic systems, providing smoother operation and reducing maintenance costs. As a vehicle owner, understanding these benefits can help you make a more informed decision when selecting hydraulic valves.

Additionally, it's essential to stay updated on the latest trends, such as the shift towards electric actuators in industrial applications. These developments not only highlight the evolving nature of hydraulic systems but also suggest that traditional hydraulic components may soon face more competition. Therefore, assessing the long-term viability of the hydraulic valves you choose is paramount to ensuring that your vehicle remains at the forefront of technological advancements.

When it comes to selecting the right hydraulic valve for your vehicle, understanding the differences between popular brands is essential. Leading manufacturers like Bosch, Parker, and Sun Hydraulics each offer unique features that cater to various automotive needs.

Bosch, known for its reliability and advanced engineering, provides options that seamlessly integrate with modern vehicles. Meanwhile, Parker is recognized for durability and versatility, making it a preferred choice for off-road and heavy-duty applications. Sun Hydraulics, on the other hand, specializes in customizable solutions that allow you to tailor valves for specific performance requirements.

Bosch, known for its reliability and advanced engineering, provides options that seamlessly integrate with modern vehicles. Meanwhile, Parker is recognized for durability and versatility, making it a preferred choice for off-road and heavy-duty applications. Sun Hydraulics, on the other hand, specializes in customizable solutions that allow you to tailor valves for specific performance requirements.

To make an informed choice, consider the following tips:

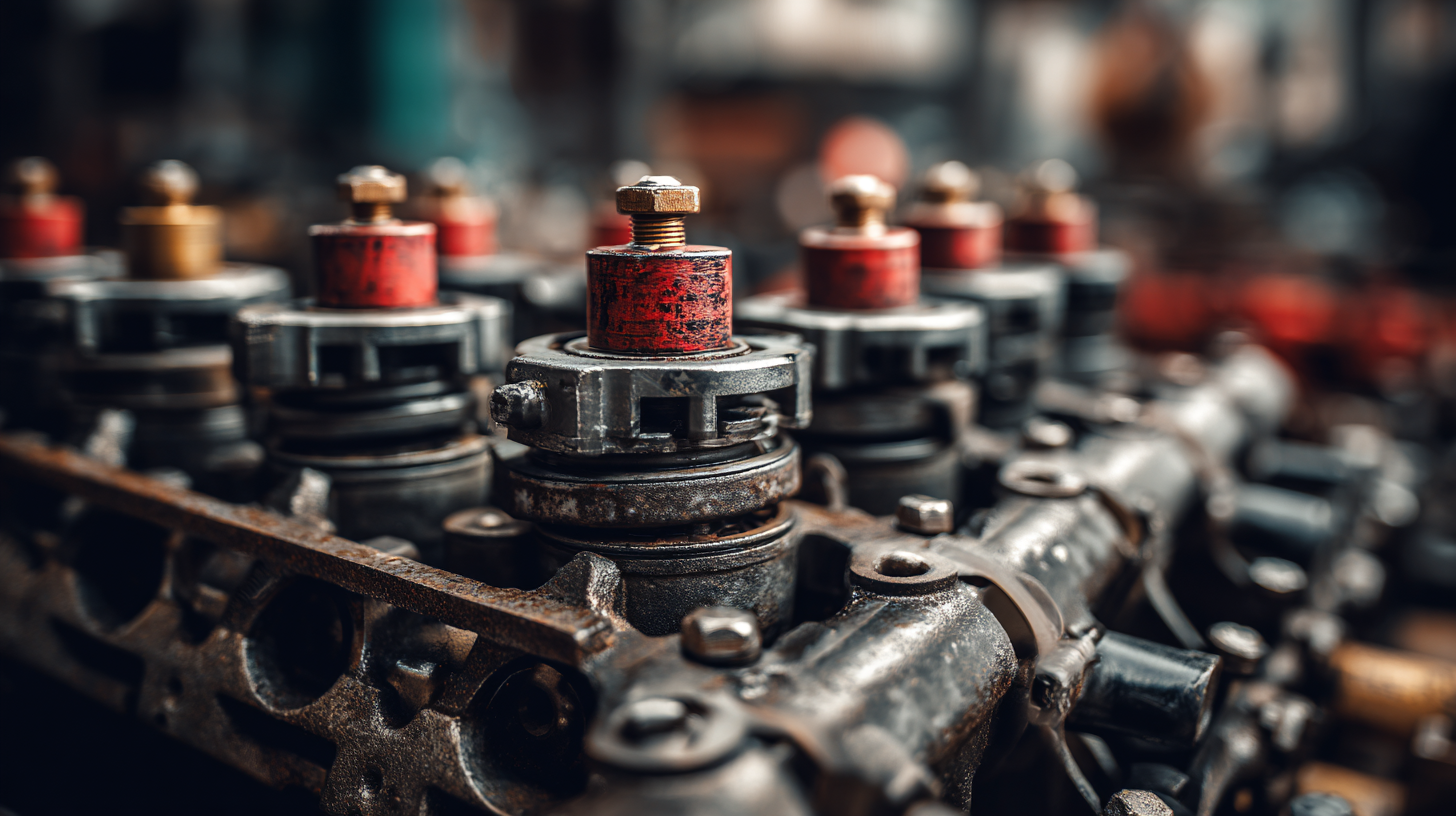

Maintaining the hydraulic valve in your vehicle is crucial for optimal performance and longevity. According to industry reports, proper maintenance can extend the lifespan of hydraulic components by up to 50%. Regular inspections should focus on checking for leaks, lubrication levels, and any signs of wear or damage. This proactive approach not only prevents costly repairs but also enhances the overall efficiency of your vehicle’s hydraulic system.

Additionally, utilizing high-quality hydraulic fluid is essential in maintaining the integrity of the hydraulic valve. A study from the Fluid Power Journal indicated that using the correct fluid can reduce energy loss in hydraulic systems by 15%, thereby improving performance. Following manufacturer guidelines for fluid changes and adhering to recommended specifications can significantly enhance the responsiveness of the hydraulic system. Implementing these maintenance tips will ensure that your vehicle's hydraulic valve operates at peak performance, ultimately contributing to a smoother and safer driving experience.