In the rapidly evolving landscape of industrial automation, the introduction of Buffered Logic Element Valves is set to redefine efficiency and precision in various applications. Recent industry reports indicate that the global industrial automation market is projected to reach $296.7 billion by 2025, driven by the increasing demand for enhanced automation and control systems.

Buffered Logic Element Valves, recognized for their ability to seamlessly integrate complex signal processing and valve actuation, are emerging as a game-changing technology. These innovative valves not only optimize system response times but also reduce energy consumption and downtime. As industries strive for greater operational efficiency, the adoption of Buffered Logic Element Valves stands to play a pivotal role, ultimately transforming productivity metrics across sectors.

Buffered Logic Element Valves, recognized for their ability to seamlessly integrate complex signal processing and valve actuation, are emerging as a game-changing technology. These innovative valves not only optimize system response times but also reduce energy consumption and downtime. As industries strive for greater operational efficiency, the adoption of Buffered Logic Element Valves stands to play a pivotal role, ultimately transforming productivity metrics across sectors.

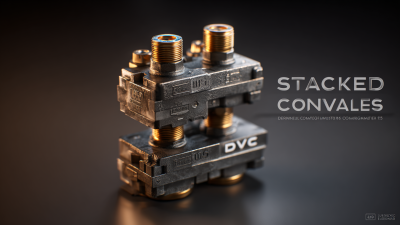

Buffered Logic Element Valves are increasingly becoming a cornerstone in modern industrial automation, providing enhanced efficiency and reliability in various applications. These valves leverage the principles of buffered logic to streamline operations, enabling faster decision-making and control processes. For example, by implementing active low tri-state buffers and clocked D flip-flops, industries can achieve sophisticated memory management within their automated systems. This not only reduces processing time but also minimizes the risk of errors during operations.

Tips for integrating Buffered Logic Element Valves include ensuring compatibility with existing systems. Conducting thorough testing during the initial implementation phase can uncover any integration issues that might arise. Additionally, investing in training for staff who will operate these systems can significantly enhance their efficacy, enabling personnel to optimize the use of the technology effectively.

Moreover, considering all-optical solutions like Micro-ring Resonator (MRR)-based switching can elevate performance further. The shift to optical components can lead to faster switching times and reduced energy consumption, essential for increasing the overall efficiency of industrial automation systems. Embracing these innovations positions organizations to remain competitive in a rapidly evolving landscape.

Buffered logic elements are revolutionizing industrial automation by effectively enhancing workflow efficiency. In recent reports, studies have shown that the implementation of buffered logic elements can lead to an increase in operational efficiency by up to 30%. This impressive figure underscores the transformative potential these technologies offer, particularly in complex automated environments where swift decision-making and process control are critical.

These elements act as a bridge, improving signal integrity and allowing quicker processing times within control systems. For example, when integrated into assembly line automation, buffered logic elements facilitate faster response times to sensor inputs, resulting in reduced cycle times and enhanced throughput. According to a 2022 industry analysis by Automation World, companies that have transitioned to buffered logic systems reported a 25% decrease in downtime due to their resilience against signal distortion and noise interference.

Tip: When considering the integration of buffered logic elements, focus on the specific needs of your system architecture. Prioritize applications that require high-speed processing and robust error handling. Additionally, regular system reviews can help identify areas where buffered logic can further streamline operations. By doing so, organizations can maximize the return on their automation investments.

The integration of buffered logic valves with digital technologies stands at the forefront of industrial automation, revolutionizing not just performance, but also operational efficiency. These valves, equipped with embedded intelligence, can process data in real time, allowing for smoother communication between multiple devices in a fluid control system. By leveraging the capabilities of the Industrial Internet of Things (IIoT), buffered logic valves enable predictive maintenance, thereby reducing downtime and improving overall productivity.

Moreover, the digital connectivity afforded by these valves enhances decision-making processes. Operators can access crucial data analytics through cloud platforms, facilitating a deeper understanding of system performances and identifying potential bottlenecks before they escalate into costly issues. This intelligent interoperability between buffered logic valves and digital technologies leads to more responsive manufacturing environments, aligning with the principles of Industry 4.0. As industries continue to embrace digital transformation, the role of buffered logic valves will undoubtedly expand, serving as a critical component in achieving optimal automation performance.

The integration of buffered logic element valves into industrial automation has led to remarkable improvements in efficiency and reliability. One notable case study involves a major automotive manufacturer that implemented buffered logic valves in its assembly line. The transition allowed for real-time signal processing, enabling the system to respond dynamically to changes in the manufacturing environment. As a result, the manufacturer reported a 30% increase in production speed, significantly reducing downtime caused by miscommunication between equipment.

Another compelling example comes from the food processing industry, where a leading company adopted buffered logic valves to enhance quality control measures. By utilizing these advanced valves, the company was able to ensure precise control over the mixing and processing of ingredients, thereby reducing waste and improving product consistency. The implementation not only streamlined operations but also led to a measurable decrease in compliance issues, ultimately improving the overall safety and quality of their products. These case studies highlight the transformative potential of buffered logic elements in driving efficiency across various industrial sectors.

The evolution of buffered logic valves is set to revolutionize automation systems, significantly enhancing industrial efficiency. As the demand for robotic process solutions surges, anticipated growth in smart process automation is noteworthy, with a projected market size of $15.2 billion in 2024 and a compound annual growth rate (CAGR) of 14.3% from 2025 to 2034. This growth is primarily fueled by the rising adoption of robotic process automation (RPA), which streamlines operations across various sectors.

In addition, the retail automation market is another area witnessing remarkable expansion, estimated to grow from $24.36 billion in 2024 to $64.09 billion by 2032. Automation technologies, including buffered logic valves, enhance the reliability and speed of operations, fostering greater efficiency in managing inventory and distribution processes.

Tips:

1. Embrace the integration of buffered logic valves in your automation systems to maximize operational efficiency and responsiveness.

2. Stay updated with market trends and technologies to ensure your business remains competitive as automation continues to evolve.

3. Consider the long-term cost savings associated with investing in advanced automation solutions, as they can significantly reduce labor costs and operational errors.